New way to form bioactive spider silk for medical use

With recent advances, technology can be used to synthesize silk with similar mechanical properties as an actual spider’s. But applying this material to promising medical therapies for illnesses such as cancer requires that humans develop a capability that only arachnids or silkworms possess – the ability to control the formation of silk.

A technique reported today in Advanced Materials offers a promising alternative to experimental silk forming methods that rely on harsh chemicals, says Associate Professor My Hedhammar , a researcher in the Division of Protein Technology at KTH Royal Institute of Technology.

Because of its strength, which is comparable to Kevlar, and high elasticity, spider silk has gained increased attention for its potential use in medicine. Researchers are hopeful that it can be used as scaffolding for tissue repair, or for drug delivery, sensing of biomarkers and for antimicrobial coatings.

But finding a satisfactory method of giving form to has proven elusive for those interested in such medical applications.

“Attempts have been made to imitate the spinning process using, for example, microfluidic systems, wet-spinning, and electrospinning,” Hedhammar says. “Many of these processes are quite complex to design and require harsh chemicals such as methanol to render the threads water insoluble after formation, which, for functionalized silk, would kill the bioactivity that’s needed for these medical uses.”

Instead, the researchers drew on recently-developed biochemistry techniques that use micropatterned surfaces in order to concentrate proteins and form organic nanowires, coatings or sheets.

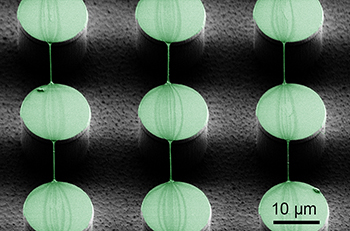

Resembling an incredibly small hairbrush, the surface the team used is comprised of micro-sized silicon pillars, which were rendered water repellent with an anti-wetting agent.

Two types of silk proteins were designed – one with an affinity to antibodies, and another with cell binding properties.

By placing droplets of the soluble silk proteins on top of the pillars, the team was able to achieve three distinct formations of synthetic silk: nanowires (which could be used in cancer therapy), local coatings (potentially useful in biomarker detection) and silk sheets (which could be used as cell growth scaffolds).

To create nanowires, for example, the researchers placed a droplet on the surface, and then dragged the droplet laterally, leaving strands of the material spanning the pillars.

Similarly, to create a sheet, the scientists left a droplet to evaporate on top of the surface. The stability of the sheets was tested by submerging them in water, as well as in a cell culture medium, for a number of days.

“The sheets remained intact, without visual signs of being dissolved, confirming that the proteins had transformed into a stable silk form,” says co-author Professor Wouter van der Wijngaart of KTH.

The paper, “Structuring of Functional Spider Silk Wires, Coatings, and Sheets by Self-Assembly on Superhydrophobic Pillar Surfaces,” was co-authored by KTH researchers Linnea Gustafsson and Ronnie Jansson, as well as Hedhammar and van der Wijngaart.

The research is funded by the Swedish Research Council (VR) and the Knut and Alice Wallenberg Foundation (KAW).

David Callahan

Read full paper: Structuring of Functional Spider Silk Wires, Coatings, and Sheets by Self-Assembly on Superhydrophobic Pillar Surfaces