Potential for magnetic cellulose comes in crisp and clear

News

Throughout the ages, Sweden has relied on its vast forests as a source of sustenance and economic growth. Now add the world’s first magnetic cellulose membrane loudspeakers to the list of products that can be produced from wood.

These flat, sonorous and environmentally-friendly speakers are made with a new material derived from wood pulp – magnetic cellulose gel – which was developed at KTH Royal Institute of Technology. Unlike ordinary speakers, they require no heavy permanent magnets.

Richard Olsson, a KTH researcher in chemical sciences who supervised the doctoral research behind the magnetic cellulose gel, says the new material may open the way for innovations in such areas as acoustic applications for automobiles.

Olsson and his colleagues at KTH, Lars Berglund, also a researcher in chemical sciences, and Valter Ström, a scientist in engineering physics of materials, recently demonstrated the speakers for the first time. Their paper is published by the Royal Society of Chemistry.

“This is, to our knowledge, the first reported magnetic speaker membrane,” Olsson says. He adds that the sound quality is at least as good as in conventional speakers – possibly better because of the even distribution of forces created in the membrane.

The idea is to show the potential of natural and environmentally-sustainable materials in everyday products. “We want to use this first prototype to see how the cellulose can be used in new applications,” he says.

He and his research colleagues have patented the material, which was created by attaching magnetic nanoparticles to cellulose nanofibrils. The cellulose comes from renewable wood pulp and involves environmentally-friendly water chemistry. The gel is cast into a membrane which is then allowed to dry. The membrane’s strength is that it has a rapid reaction capability, which means a high degree of precision in sound reproduction.

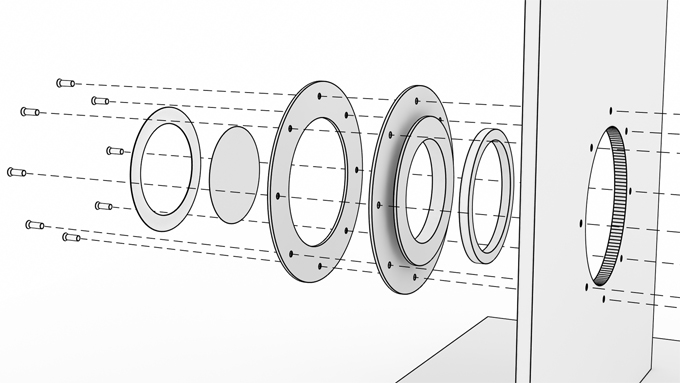

Ordinary speakers include a large permanent magnet. The speaker cone's movement, which creates sound waves, is driven by a voice coil that is wrapped around the permanent magnet and attached to the cone.

With the cellulose membrane speakers, the magnetic particles are part of the membrane itself. The KTH speaker has a coil, but it has no direct contact with the cone, so the only thing that creates sound is the movement of air. All of these components can be manufactured at a very small scale.

The technology has potentially other uses, he says. “We want to look at applications for the material that are driven by magnetic fields. It may, for example, be a form of active damping for cars and trains.” It could also involve technology that cancels out noise.

Research in materials from the Swedish forests is conducted at Wallenberg Wood Science Center (WWSC). The doctoral students in the project are Sylvain Gallan, Richard Andersson and Michaela Salajkova.

For more information contact:

Richard Olsson +46 (0) 8-790 60 36 or +46 (0) 73-270 18 68; Richard @ polymer.kth.se

Lars Berglund 08-7908118; blund @ kth.se.

Read the report: