Wheat gluten can be used to make sustainable diaper material

More sustainable diapers are one possible use for a new bio-based material that researchers in Sweden are developing. The superabsorbent material is made with wheat gluten proteins from wheat starch processing, without directly competing with food resources.

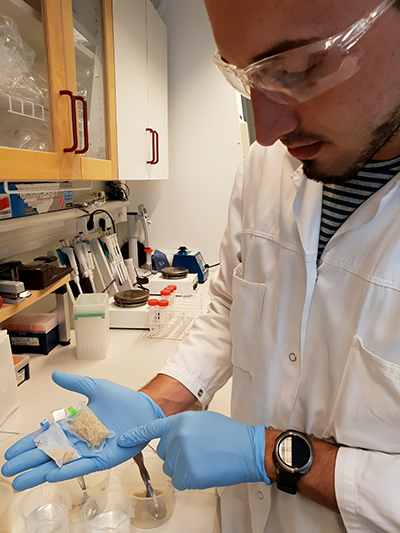

Antonio Capezza , a researcher in at KTH Royal Institute of Technology and SLU Swedish University of Agricultural Sciences, says the material is capable of swelling up to 4,000 percent in water and 600 percent in saline solution.

The worldwide disposable diaper market is expected to reach more than $55 billion by 2025, and many of these products consist of fossil-based absorbent components. “This is an opportunity to increase the use of renewable materials in diapers and meet the growing need for health and hygiene products,” Capezza says.

Capezza says the next step is to scale up production of the material so that the researchers’ industrial partners can test it in different applications. “By developing bio-based solutions then we are contributing toward a circular bio-economy and possibly new business opportunities and partnerships,” he says.

In order to create a fully sustainable alternative, the researchers are focusing only on agricultural side-streams, or co-products. “If we want to be sustainable, we need to use raw materials that are renewable and that are not going to interfere with the main food production chain in the future,” he says.

The water absorbency of the new material matches that of other bio-based alternatives. This includes products made with raw materials that are not obtained as a co-product, Capezza says. A research paper, which was published in Advanced Sustainable Systems , indicates that the material could be further engineered to eventually match the absorbency of petroleum-based synthetics.

The market for superabsorbent materials extends beyond disposable diapers, but Capezza says that diapers are the most demanding in terms of urine absorption properties. “By aiming to match or exceed the absorbency performance of petroleum-based superabsorbents used in many disposable diapers, we can meet the standards for most other applications that require superabsorbents.”

Highly absorbent materials are used in personal care and medical products, as well as in flood water mitigation and rain water retention for agriculture, among other formats. Capezza says the next step is to scale up production of the material so that the researchers’ industrial partners can test it in different applications.

A co-product from industrial production of wheat starch and ethanol production, wheat gluten is composed of proteins that make it a promising material for absorbency applications. The researchers enhanced the swelling potential of the wheat gluten polymer by changing the chemistry of the gluten to more resemble that of synthetic material, and crosslinking the molecules with plant extracts from the fruit of gardenia jasminoides.

Working with the researchers from KTH were colleagues at SLU and Kyoto University in Japan. The project was founded by VINNOVA, in collaboration with Lantmännen and Essity.

David Callahan

Superabsorbent Polymers: High Capacity Functionalized Protein Superabsorbents from an Agricultural Co‐Product: A Cradle‐to‐Cradle Approach , Advanced Sustainable Systems, doi: 10.1002/adsu.202070018