This course reviews strategies for fabrication of nanostructured functional materials from building blocks with at least one dimension less than 100 nm. It aims at teaching the students a variety of solution based chemical techniques that are commonly used for the fabrication of nanostructured materials.

A general introduction on materials chemistry starting from the atomic level to the formation of crystals/solids and crystal structures, intermolecular and intramolecular forces, molecular structures, stoichiometric calculations will be presented in the beginning. Bottom up strategies for the fabrication of nanostructured materials with a higher flexibility of controlling materials’ microstructure will be emphasized. Solution based techniques will be prioritized in order to emphasize the significance of prior chemical knowledge in making the desired materials.

Specifically the following nanomaterials fabrication techniques will be covered:

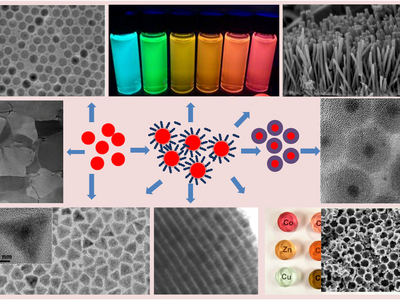

Solution co-precipitation, thermodynamic modeling; sol-gel synthesis; redox reactions and electrochemical synthesis; microemulsion synthesis; thermolysis. Self-assembly, or directed assembly, process, related chemical principles, and its use for the fabrication of higher order nanostructures will be presented. After introducing all these techniques, pros and cons will be discussed and several examples of their implementation in materials science will be presented.

This course will give a detailed theoretical background to a variety of solution chemical techniques that are used for the fabrication of nanomaterials.

After a successful completion of the course, students should be able to:

- Describe and distinguish between different models of chemical bonding (ionic, covalent, metal) and propose dominant bonding type in compounds.

- Establish Lewis structures, including resonance and alternative forms, determining VSEPR-formulas and geometry of chemical compounds and (for simple compounds) indicate hybridization.

- Draw the shape of simple molecules, show the bonding scheme and charge on each atom.

- Describe bottom-up and top-down strategies for making nanostructured materials.

- List solution based techniques used for the fabrication of nanomaterials.

- Describe co-precipitation technique and compare it with other solution based techniques.

- Describe sol-gel technique and compare it with other solution based techniques.

- Describe microemulsion synthesis technique and compare it with other solution based techniques.

- Explain the underlying principle of morphology and size control in solution-based fabrication techniques.

- Describe redox reactions and explain the principles of electrochemical process for fabrication of nanostructured materials.

- Describe self-assembly route, explain the underlying principle for the fabrication of nanostructured materials.

- Give examples of nanostructured materials fabricated via self-assembly route.

- Describe directed-assembly route, explain underlying principles.

- Describe mesocrystals and their formation using self-assembly principles.

- Suggest possible strategies for fabrication of a nanomaterial with given complexity.

- Design a strategy/strategies for the fabrication of nanomaterials with defined composition, morphology and size constratints.

- Perform literature survey on phycial and chemical fabrication routes.

- Present a project report in writing and orally.