| Criterion |

|

|

|

|

|

Main topic: this will take approximately 5-6 pages and will include one of the following types of powder technology:

- production

- characterisation

- consolidation

|

30 to >24 Pts

Excellent

You construct an efficient and effective argument about why your chosen technology/technologies are the best for the situation you have been asked to consider. You consider all relevant information and connect different arguments together to create an overall argument.

|

24 to >16 Pts

Good

You consider most of the scientific issues surrounding the problem you are asked to solve with a good level of detail, or you consider all of the relevant issues in some detail, but the level of detail could be improved. You have not discussed any issues that are irrelevant.

|

16 to >8 Pts

Average

You consider some scientific principles that are relevant for your problem, but you also miss several important points, or do not discuss the points in enough detail. One or two of the issues you discuss are not relevant to the problem you have been asked to solve.

|

8 to >2 Pts

Poor

You include almost no relevant information to solve the problem you have been set in your assignment. You either present too little information, or discuss irrelevant information.

|

2 to >0 Pts

Very poor

You do not include any relevant information to find an answer for the situation you are asked to consider in your assignment.

|

|

Secondary topic: this will take approximately 1-2 pages and is another of the three topics listed in the "main topic":

- powder production

- characterisation

- consolidation

|

10 to >8 Pts

Excellent

You have described many relevant scientific issues, relating to the problem you have been asked to consider and have provided information to cover the topic thoroughly.

|

8 to >4 Pts

Good

You have included at least three relevant scientific issues for the problem you have been asked to consider and none of them are inappropriate or incorrect.

|

|

4 to >0 Pts

Poor

You have not included more than two relevant scientific comments for the problem you have been asked to consider, or multiple statements are simply incorrect.

|

|

| Sustainable development: 1-2 pages answering the questions set i your assignment that deal with the area of sustainable development, including health and safety. |

10 to >8 Pts

Excellent

You include the required number of discussion points for the problem you have been asked to consider and all are correct, relevant and described well.

|

8 to >4 Pts

Good

You include multiple relevant discussion points, but not the number you were asked to provide. Alternatively, one of your discussion points is completely incorrect or irrelevant. Alternatively, you include enough discussion points, but do not include enough explanation or detail to answer the question(s) you have been asked to consider.

|

|

4 to >0 Pts

Poor

You fail to consider sustainable development, or include discussion that is irrelevant for the problem you have been asked to consider.

|

|

| Citations: inclusion of appropriate citations for any information you include that is not found in the course material. |

4 to >2 Pts

Excellent

You have included citations to the information that you have collected form sources other than the course material. The citations are detailed enough that the information could be found by a reader.

|

|

2 to >0 Pts

Average

You have either not taken any information form sources outside the course material, or you have provided some good citations, while missing others, or you have cited information but not well enough to let a reader find the information easily.

|

0 Pts

Poor/missing

You have taken information from sources but have not cited them at all.

|

|

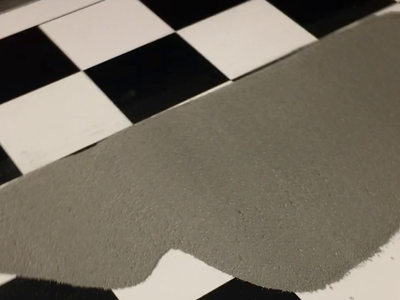

| Language and figures: the quality of language in your report, as well as the clarity and usefulness of any images, graphs, tables, etc. you include.

You should present graphs, tables, images, etc. if they improve the quality of your report, but you do not need to do so to achieve the top grade, as long as you present information in the most appropriate way in your report. In other words, if you choose to not use graphs, tables, images, etc. and it would make your report better if you did include them, you may lose points. If your report would not be improved by including images, graphs, tables, etc. then you will not lose points if you do not include them.

|

6 to >4 Pts

Excellent

There are only a few mistakes in your English and the meaning of your writing is clear.

|

4 to >2 Pts

Good

There are only minor mistakes in your English, but the meaning of your writing is fairly easy to understand.

|

2 to >0 Pts

Average

There are many mistakes in your English, but the general meaning can still be understood.

|

0 Pts

Poor

Your use of English is so poor that it is very difficult to understand. You may also lose marks form other assessment criteria as a result, if you fail to demonstrate the required knowledge as a result of the standard of your English.

|

|