Construction and Engineering Materials

Large-scale research infrastructures are essential for advancing the understanding and development of engineering materials, including metals, alloys, ceramics, and composites. Synchrotron radiation and FELs provide extremely bright and tunable X-ray beams that allow scientists to probe materials at multiple length scales — from atomic structures to macroscopic properties.

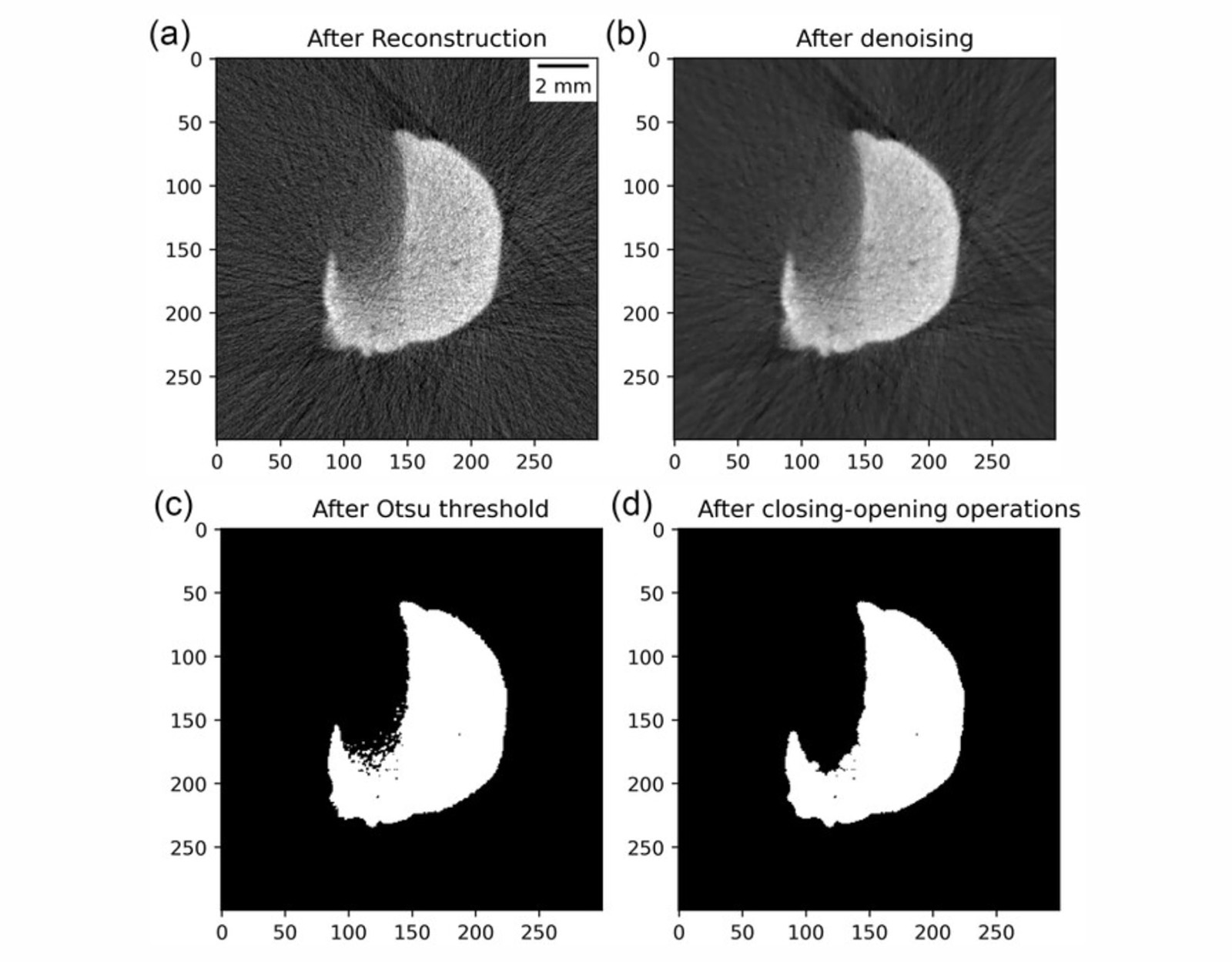

Large-scale research infrastructures enables detailed investigations into crystal structures, defects, strain distributions, and interfaces, all of which are crucial for tailoring materials with improved mechanical strength, corrosion resistance, and thermal or electrical performance. These tools also permit in situ and operando studies, where materials can be examined under real operating conditions such as high temperatures, pressures, or stresses, yielding insights that are directly applicable to industrial processes and product development.

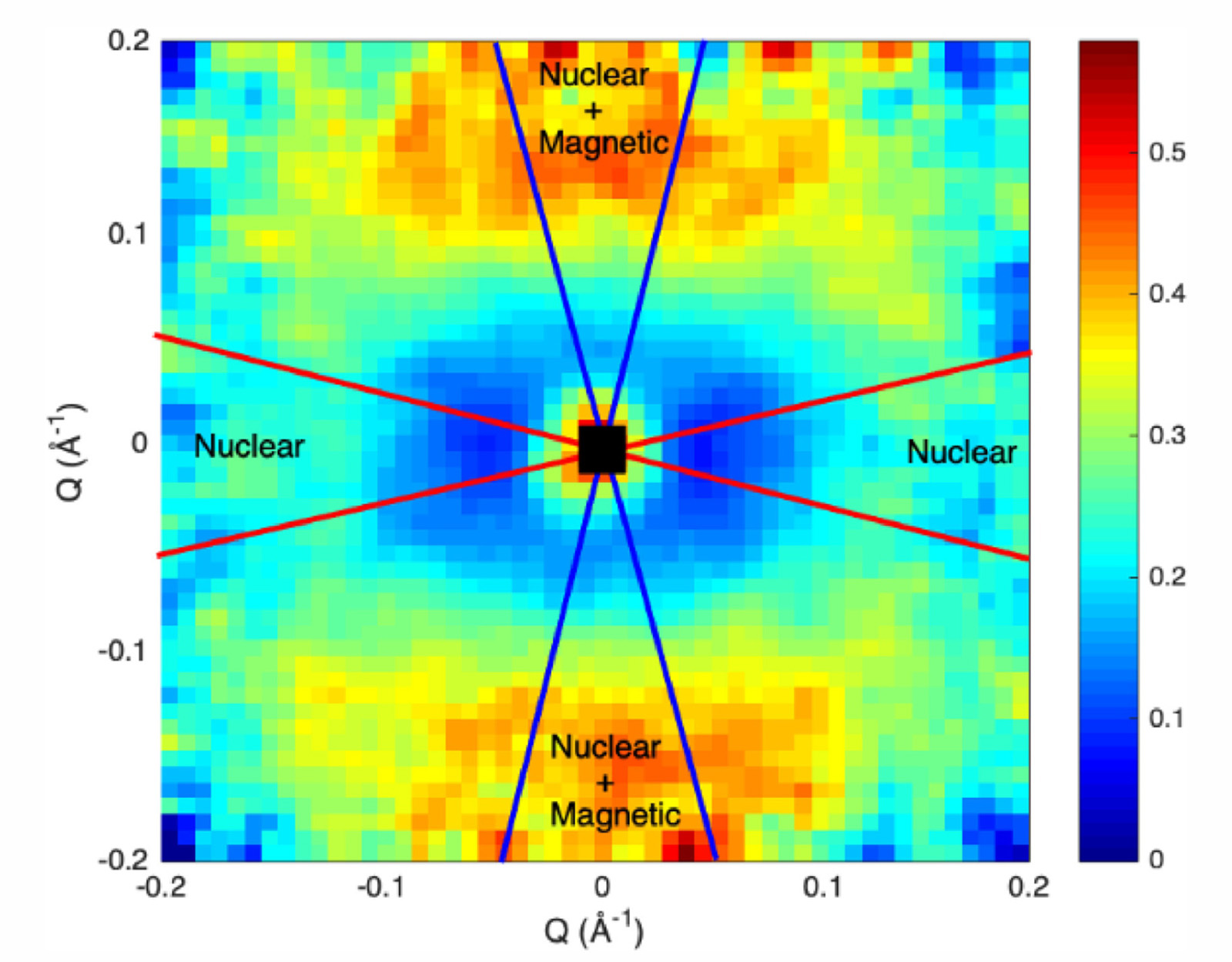

Neutron and muon sources provide complementary information that is often inaccessible with X-rays. Neutrons, with their deep penetration and sensitivity to light elements, are particularly well-suited for studying bulk materials, magnetic properties, and hydrogen behavior in metals. Muons, in turn, can probe local magnetic environments and diffusion processes at the atomic scale, offering valuable data for understanding phase transformations, aging, and degradation mechanisms. Together, these facilities enable a comprehensive picture of materials behavior, supporting the design of next-generation engineering materials with enhanced performance, sustainability, and reliability.

Sweden has a long and proud tradition in engineering materials, rooted in its strong industrial base and culture of innovation. From high-performance steels and advanced alloys to cutting-edge composite and functional materials, Swedish research and industry have long collaborated to drive progress in sectors such as manufacturing, energy, and transportation. Central to this success is KTH Royal Institute of Technology, one of Europe’s leading technical universities, which has played a pivotal role in advancing materials science and engineering for decades. KTH’s research excellence — spanning metallurgy, nanomaterials, and sustainable manufacturing — is closely linked with industrial partners, ensuring that scientific breakthroughs translate into real-world applications. Large-scale research facilities such as MAX IV and the European Spallation Source (ESS) further strengthen this ecosystem by providing Swedish researchers and companies, including those at KTH, with access to world-leading tools for studying materials at the atomic and microstructural levels. Together, Sweden’s industrial strength, academic excellence, and advanced research infrastructures form a powerful foundation for continued leadership in materials innovation and sustainable technological development.

Examples