EK2360 is a project course worth 7.5 ECTS credits, which is equivalent to 200 work hours of full-time study. As the course runs about 8 weeks, this implies that about 25 hours a week must be devoted to various course activities, including introductory lectures and reading of course material, together comprising about 20% of the course activities, and carrying out the project work, which comprises 80% of the course work.

The introductory lectures on basic MEMS design and fabrication, with special focus on the following project work, will be taught by the course responsible. Attendance of the introductory lectures is compulsory.

After the introductory lectures, a brief written intermediate examination will be carried out, assessing whether the knowledge and understanding of the student is sufficient for continuing with the actual project work.

The project work is supervised by senior PhD students and the course responsible.

The report writing and the final presentation and a brief post-discussion are supervised by the course responsible.

During the course, the student will gain in-depth knowledge and understanding on microsystems, with emphasis on different micro-electromechanical actuator types, on their working principles, concept and design, process technology, clean-room fabrication, device characterization, and failure analysis. Upon successfully completing the course, the student will be able to:

- develop different concepts of microsystem actuators for real-world applications

- design microsystem devices and adapt them to different application requirements

- predict the behaviour of microsystem devices by (1) qualified guessing based on general understanding of the microsystem and the application; (2) rough estimation by using/adapting text book formulas; (3) accurate modelling and simulating by modelling using state-of-the-art multi-physics finite-element based design tools (FEM)

- work out design concepts under consideration of fabrication-technology limitations

- develop a fabrication process flow

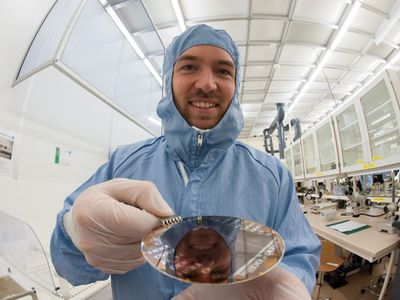

- carry out basic microsystem fabrication steps in a class-100 clean-room environment under the safety requirements of such an environment

- characterize the devices for their electrical, mechanical, and thermal behaviour

- identify failure mechanisms, conclude on device limitations and reflect on device improvements based on the characterization results of the prototype devices

- write a project report summarizing design, fabrication, characterization, failure analysis, and potential future device improvements

- present and defend the results to a critical audience

- work in a small microsystem development team, including taking management responsibility from project plan writing to work distribution and task assignment to the team members