Fusion Technology: Scope of the field.

Scope and structure of the course, requirements for approval.

Introduction to fusion and reactor construction: D-T fusion and energy release, main reactor components.

Underlying physics and chemistry in plasma – material interactions.

Mechanisms of wall erosion and their impact on plasma contamination: Erosion and re-deposition, mechanisms (underlying physics), erosion yield and material lifetime. Dust formation and risk related to dust. Fuel inventory.

Power loads and power handling in steady-state operation and in transient events

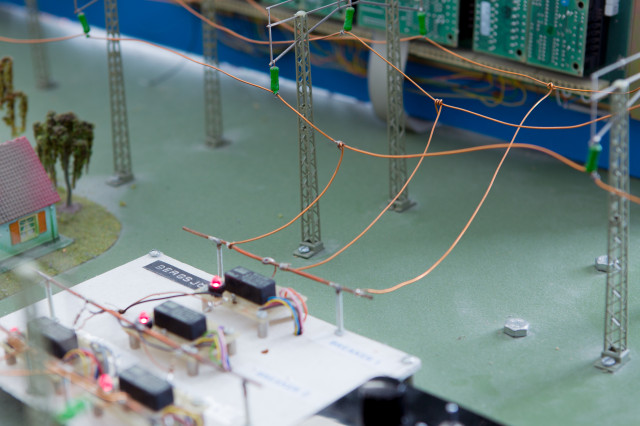

Wall components for a reactor-class machine: structure, testing of wall materials and components, test-beds.

Selection of armour materials for controlled fusion devices.

Materials for diagnostic components: ceramics.

Radiation induced damage in fusion reactor materials: definitions: displacement per atom, transmutation, neutron-induced effects (details), influence on ceramic materials.

Concept of IFMIF (International Fusion Material Irradiation Facility).

Tritium breeding blanket: blanket structure, structural and functional materials.

Tritium handling: tritium plant, remote handling and safety aspects.

Analysis of fusion reactor materials: methods for surface and bulk analysis, instrumentation (visit to laboratory).

Organisation and coordination of Fusion Research (Technology & Material Programme).

ED2240 Introduction Course to Fusion Technology 6.0 credits

The course is designed for physicists and engineers who want to learn about technology and properties of wall materials applied under extreme conditions in operation of a reactor-class fusion device. The completion of the course should provide background for future work at fusion physics laboratories and fusion-related industry.

Information per course offering

Choose semester and course offering to see current information and more about the course, such as course syllabus, study period, and application information.

Information for Autumn 2026 TEFRM programme students

- Course location

KTH Campus

- Duration

- 24 Aug 2026 - 23 Oct 2026

- Periods

Autumn 2026: P1 (6 hp)

- Pace of study

50%

- Application code

10746

- Form of study

Normal Daytime

- Language of instruction

English

- Course memo

- Course memo is not published

- Number of places

Min: 1

- Target group

- Open for all programmes, as long as it can be included in your programme.

- Planned modular schedule

- [object Object]

- Schedule

- Schedule is not published

Contact

Course syllabus as PDF

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus ED2240 (Autumn 2024–)Content and learning outcomes

Course contents

Intended learning outcomes

After passing the course, the student should be able to

- describe and distinguish different mechanisms of wall erosion and fuel retention

- explain and assess the impact of physical and chemical processes on erosion of wall material

- critically assess and motivate material choice for respective plasma-facing components

- compare and assess fuel inventory in different wall materials and assess its impact on the fuel cycle

- evaluate power loads to the wall during normal operation, disruptions and edge localised modes

- relate thermo-mechanical properties of materials (CFC, W, Be) to their response to power loads

- relate wall erosion to its impact on plasma operation

- explain causes for dust formation and assess the risk of such process for the reactor operation

- select methods for studies, analysis and qualification of wall materials

- apply knowledge to experiment planning and conceptual design of: diagnostic for erosion-deposition measurement and propose the use of diagnostic for specific experiments in a controlled fusion device; plasma-facing components for testing under reactor conditions

in order to be able to

- solve scientific or technical problems in fusion science and technology

- communicate with scientific and technical staff at fusion laboratories

- communicate with teachers and students at summer schools on fusion plasma physics

- present results and ideas.

Literature and preparations

Specific prerequisites

Knowledge in physics, 7,5 credits, equivalent to completed course SK1108.

Recommended prerequisites

Students with good knowledge of physics and electromagnetics.

Literature

Examination and completion

Grading scale

Examination

- SEM1 - Seminars, 2.0 credits, grading scale: A, B, C, D, E, FX, F

- KON1 - Partial exam, 2.0 credits, grading scale: A, B, C, D, E, FX, F

- TEN1 - Written exam, 2.0 credits, grading scale: A, B, C, D, E, FX, F

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.

SEM1 includes an oral presentation and written report of project, two structured hand-ins (student seminars) and oral presentation of problem-solving (seminar).

KON1 is a written partial exam.

Examiner

Ethical approach

- All members of a group are responsible for the group's work.

- In any assessment, every student shall honestly disclose any help received and sources used.

- In an oral assessment, every student shall be able to present and answer questions about the entire assignment and solution.