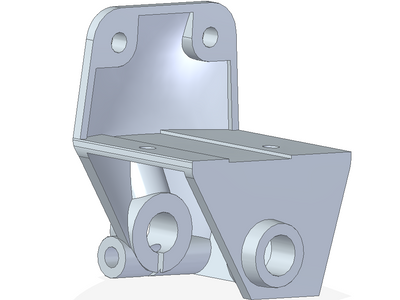

Advanced CAD usage:

- Advanced solid modelling operations

- Modelling of parts with complex shapes and freeform surfaces

- Diverse and unconventional metodologies for CAD work

- Modelling operations for sheet metal parts

Manufacturing adaptation and preparation for manufacturing in Rapid Prototyping equipment