1. Explanation for the use of metal powder

2. Methods for metal powder production

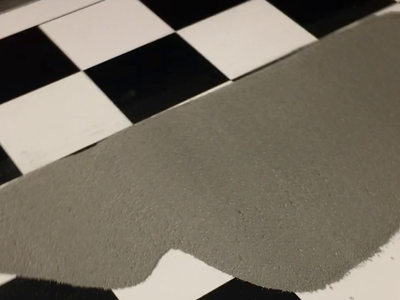

3. Powder properties and characterisation methods

4. Handling of metal powder

5. Process paths for production of components from metal powder

Metal powders are vital for many processes, including additive manufacturing, sintering, isostatic pressing and metal injection moulding. This course gives covers the science of metal powder production in depth, focusing on key technologies and properties.

The way in which powders are characterised is also a major focus of this course: what properties are important? How can they be measured? What problems can there be in measurements?

Even the most advanced and successful powder production processes is useless unless the powders are stored and handled correctly. This and potential hazards of metal powder will be considered.

This course builds on knowledge gained in MH2100. If you did not take MH2100, introductory material will be available during the course.

This course has been designed so that you are in control. Information will be made available using videos, texts and formative quizzes in Canvas. Lectures will focus on advanced areas, industrial challenges and issues of metal powders and sustainability.

The course is examined in three parts: a lab exercise, a written exam and an assignment that is based on a feasible industrial scenario.

This course has been created by project "Utbildning i produktion av metallpulver – Framtidens arbetskraft i Sverige (UPP-FAS)" (reference number 2018-00794), within the strategic innovation program Metallic Materials, a joint initiative by Vinnova, Formas and the Swedish Energy Agency.

KTH Campus

Autumn 2026: P2 (6 hp)

33%

10906

Normal Daytime

English

Min: 10

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus MH2101 (Autumn 2020–)1. Explanation for the use of metal powder

2. Methods for metal powder production

3. Powder properties and characterisation methods

4. Handling of metal powder

5. Process paths for production of components from metal powder

After passing the course, the student should be able to:

Basic knowledge of processes for production of powder metallurgical products (minor essay and AM) and thermodynamic and physical bases of melt systems' solidification, equivalent to course MH1024 Fundamentals of Materials Science - Metallic Materials, or the equivalent.

Basic knowledge in fluid dynamics of melt systems equivalent to the course MH1018 Transport Phenomena, or the equivalent.

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.