Seminarieserie som ger en bred bild mikrosystemtekniken samt en fördjupad insikt i tekniska lösningar för de vanligaste tillämpningarna.

- De introducerande seminarierna ger en introduktion till tillverkningstekniken och de fundamentala fysikaliska principer som utnyttjas inom området.

- Därefter ges en detaljerad översikt av mikrosystembaserade sensorer för mätning av läge, töjning, acceleration, temperatur, tryck och flöde.

- De avslutande seminarierna illustrerar mikrosystemteknikens tillämpningar inom specifika tillämpningsområden, såsom medicinsk teknik och fordonsteknik.

- En gästföreläsare från industrin beskriver hur mikromekanik tillverkas industriellt. Föreslösningen ger också exempel på hur framsteg inom mikrosystemtekniken kan kommersialiseras.

- En annan gästföreläsare ger en kort introduktion till det närliggande ämnet nanoteknologi

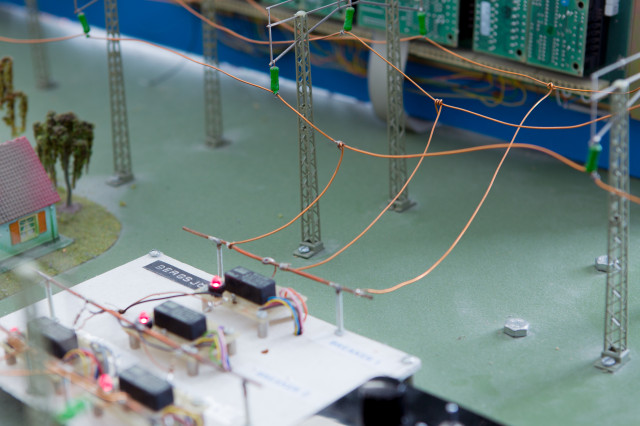

Det övergripande målet för kursen är att ge en introduktion till mikrosystemteknikens värld, det vill säga till komponenter och system med mått från mindre än en millimeter ned till 100 nm. Detta område kallas ofta även ”MEMS” – Micro Electromechanical Systems. Speciellt behandlas fysikaliska principer för sensorer och aktuatorer inom mikrotekniken, mikrofabrikationens metoder, design och användning av de vanligaste mikrosystemkomponenterna och slutligen användning av mikrosystem i några viktiga tillämpningsområden.

Efter genomgången kurs kommer studenterna att

• för

- de fysikaliska principerna för sensorer, aktuatorer, även sådana för mikrofluidik

- tillverkningsteknik för mikrosystem i kisel,

- de viktigaste typerna av optiska sensorer, mekaniskt resonanta sensorer, sensorer för tröghetsnavigering, sensorer för flöde, tryck och termiska storheter samt komponenter för mikrofluidik och för elektroniktillämpningar

kunna

- ge en översikt över de vanligaste metoderna och teknikerna,

- förklara hur dessa fungerar och kan tillämpas,

- jämföra deras fördelar och nackdelar,

- använda sina kunskaper för att på ett strukturerat och professionellt sätt bearbeta tekniska utmaningar inom mikrosystemtekniken;

• för viktiga tillämpningar inom medicinsk teknik, fordonsteknik, bioteknik och inom optisk och elektronik kommunikationsteknik

kunna

5. diskutera mikrosystemteknikens potential när det gäller storlek, kostnad och prestanda.

Dessutom kommer studenterna att ha en viss erfarenhet av arbete i renrum och experimentell utvärdering av mikrosystemkomponenter.