Ibrahim Onifade

About me

Academic Background

Lic. Eng. in Transport Infrastructure, KTH Royal Institute of Technology, 2015

M.Sc. in Infrastructure Engineering, KTH Royal Institute of Technology, 2012

Research project: Asphalt Concrete Micro-mechanical Modelling and The Development of an Energy-based Damage and Fracture Framework for Asphalt Concrete.

Research team: PhD student Ibrahim Onifade (KTH Building materials), Prof. Björn Birgisson (KTH Building materials), Romain Balieu (KTH Structural design and bridges)

Asphalt Concrete Micro-mechanical Modelling

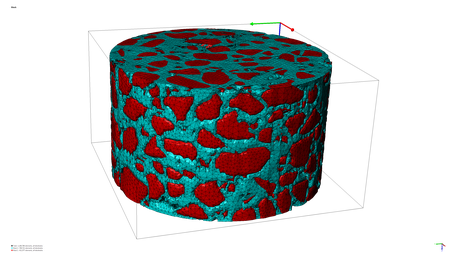

Asphalt mixtures are heterogeneous materials at several length scales. At meso-scale, they consist of aggregates, bitumen-based binder and air voids. The morphology of the asphalt mixtures may be defined as a set of parameters describing the geometrical characteristics of the constituent phases, their relative proportions as well as spatial arrangement in the mixture. In particular, the morphology of asphalt mixtures is of considerable practical importance at the meso-scale, as it has been shown in several studies that the deficient internal structure of the material results in compromised performance in the field.

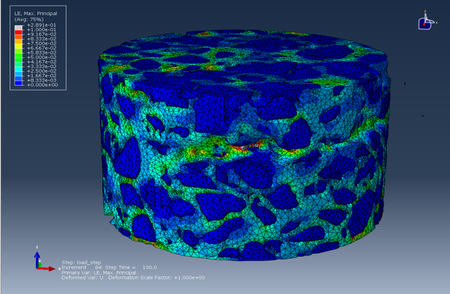

The objective of the micro-mechanical analysis of asphalt concrete mixtures is to investigate the effect of changing microstructure and morphological parameters on the stiffness and strength properties of asphalt concrete mixtures. X-ray computed Tomography (CT) is used to acquire the internal structure of the asphalt mixtures and Digital Image Processing (DIP) techniques are used for the identification and segmentation of the individual faces. Numerical simulation of different mechanical loadings is then performed using Finite Element Analysis (FEA) to characterise the mixture's mechanical properties and performance.

|

|

| Figure 1: Phase-segmented image of asphalt concrete showing stones, mastic and air-voids. |

Figure 2: Contour plot showing strain distribution and strain localization in the mastic phase. |

Energy-based Damage and Fracture Framework for Asphalt Concrete.

Asphalt concrete is a viscoelastic composite construction material which consists of stones, sand and filler, blended with, and held together by a binder, typically bitumen or polymer modified bitumen. Damage in asphalt concrete is a result of changes in the microstructure of the material due to the application of external load and the effect of varying environmental conditions – temperature and moisture. These changes in microstructure result in different observable failure modes depending on the temperature range and can be mainly characterized as cracking or plastic deformation. The first part of this research is focused on the development of a failure law due to cracking in asphalt concrete pavements.

Most of the existing asphalt concrete damage models have been developed with focus around predicting the crack performance at intermediate temperatures despite the fact that the material is exposed to a wide range of temperature during its service life. It should be noted that in the range of service temperatures, the matrix binder stiffness varies significantly by some orders of magnitude from low to high temperatures. Due to this stiffness variation between the aggregate inclusions and the matrix binder, different damage mechanisms i.e. cracking and plastic deformation are dominant at low and high temperatures respectively at a moderate strain rates. This research suggests the possibility of developing two different potential-based models to accurately characterize the material behavior at low and high temperatures respectively. One of the models will focus on the characterization of cracking at low temperatures, while the other model will be used to characterize the plastic deformation at high temperatures. Both models can then be coupled to characterize the material at intermediate temperature. The work when finished will provide improved prediction of material response at extreme temperatures i.e. low and high temperatures, while minimizing material prediction errors at intermediate temperatures.

Courses:

- Finite Element Methods in Analysis and Design (AF2024) Assistant

- Advanced Pavement Engineering Analysis and Design (AH2905) Assistant

- Advanced Rheology of Bituminous Materials (FAF3901) Teacher