Tania Loaiza Uribe

About me

I am a materials engineer. I am interested in Metallic materials and mechanical properties to improve the performance in different industry areas. My focus is to investigate the influence of different microstructures and chemical compositions in the rolling contact fatigue performance. Besides providing solutions to actual industrial regarding fatigue problems.

Background

- Materials Engineer from Universidad de Antioquia, Medellin- Colombia. Program equivalent to 210 ECTS). " Stability of retained austenite under deformation conditions in multiphase steels with nanostructured bainite" Nanostructured bainite

- Doble degree Master’s in Advanced Material Science and Engineering (AMASE), Program equivalent to 120 ECTS). Universitat Politectnica de Catalunya and Luleå Tekniska Universitet. Wear and microstructural characterization of Advanced High Strength Steels (AHSS) in Crusher application

Advances courses in:

- Contact fatigue

- Fatigue of materials- mechanics and test methods

- Phase transformation of steels

- Material mechanics

PhD research

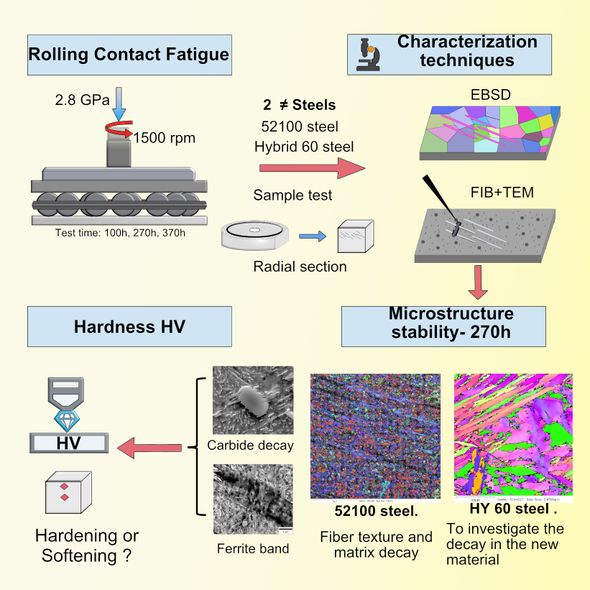

Industrial Ph.D. student, collaboration with Ovako steels, in the study of the initiation of fatigue in 100Cr6 and Hybrid 60 steel. (Hybrid steel- Ovako) under rolling contact fatigue for bearing applications.

Hybrid Steel and Its Potential for Bearing Applications

In the automotive bearing Steel industry, a new design of material with high-performance material is required, which allows improving the fatigue life. Usually, bearing components operated under high loads 1.8-2.5 GPa and temperatures (100-200°C) that can generate microstructural degradation after a specific cycle’s number, leading to failure due to a fatigue life reduction. Hybrid 60 is a new material developed by Ovako that combines secondary hardening and intermetallic precipitates. Dual hardening steel could be a potential material to increase fatigue life. However, there are no studies of this material in bearing applications, being one of the motivations of the PhD project.

The following image shows a summary of the test and characterization techniques: