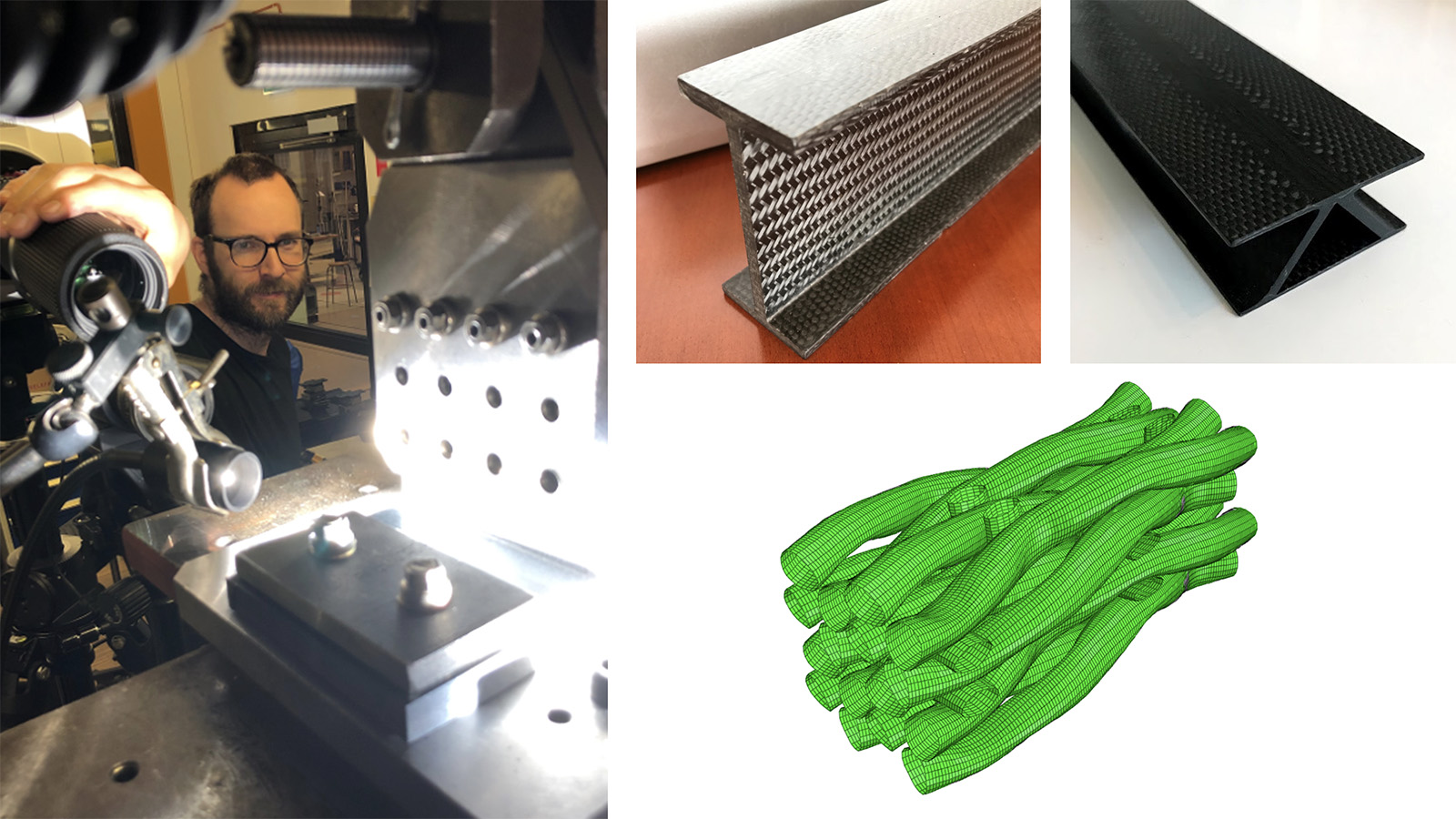

Development of 3D-weaving technology – machines, simulations and products

3D-weaving is a new production method invented by the SME Biteam and developed in collaboration with KTH. It enables production of complex 3D shapes from yarns, where advanced structural materials such as carbon fibres can be woven into a wide range of beam profiles. Two consecutive EU projects and a number of domestic projects have developed the machine technology, methods and tools for simulation and analysis, and investigated various solutions together with industrial partners.

The 3D weaving technology

3D weaving was invented relatively recently compared to other textile production methods that are thousands of years old. A unique architecture and development of new innovative machine solutions enable automated production of a new class of textiles. Woven 3D shapes are generated directly from yarns in a single production step, enabling a paradigm shift in composite manufacturing, and offering new, beneficial material properties.

The main field of application for the technology is fibre-reinforced composite materials for the aerospace industry and other producers of high performance lightweight materials. Significant reduction of scrap material is also a great asset for sustainability.

Industry impact and recognision

KTH and Biteam have collaborated in several projects together with many of the major aerospace companies in Sweden and Europe, where they have developed the technology, designed components and built machines for the realisation of the products.

The work has been backed by KTHs efforts to test, characterise, simulate and analyse the fibre preforms and the resulting composite parts. The research has been part of four doctoral theses at two universities and Biteam has become a reputable provider of unique fibre solutions within the composite and aerospace businesses.

Project contacts