Breakthrough for KTH’s energy research makes sustainable hydrogen production safe and more efficient

Hydrogen is expected to play a key role in the transition to a climate-friendly energy system. However, producing hydrogen using existing techniques is associated with a degree of risk and requires special membranes that are expensive and needs precious metals to be sufficiently efficient. Newly published research from KTH points the way to a safer and more cost-effective approach.

Hydrogen is set to be part of tomorrow’s sustainable energy system in a number of ways, including as a process gas in industrial applications, energy storage, for balancing grid energy and as an energy carrier for vehicles. Hydrogen offers considerable climate benefits when it is produced using electricity from sustainable energy sources such as solar and wind.

“One of the problems with today’s technologies for converting water into hydrogen gas is that they result in dangerous combinations of hydrogen and oxygen. We have developed a two-stage process where we completely separate the production of oxygen and hydrogen, which makes it entirely safe,” says Joydeep Dutta, Professor in Materials and Nanophysics at KTH.

KTH Energy Platform first met Joydeep Dutta in 2021 during a visit to the then recently opened Campus Albanova. Professor Dutta was also involved in KTH research platform Materials and Energy’s presentation of cutting-edge research together with IVA.

Fossil-free production of hydrogen

The fossil-free production of hydrogen involves the use of a so-called electrolyzer, which splits water molecules into hydrogen and oxygen with the help of electricity to create hydrogen and oxygen. The most common electrolyzers use an internal membrane to separate hydrogen gas from the oxygen gas. But successfully separating the two gases entirely is virtually impossible.

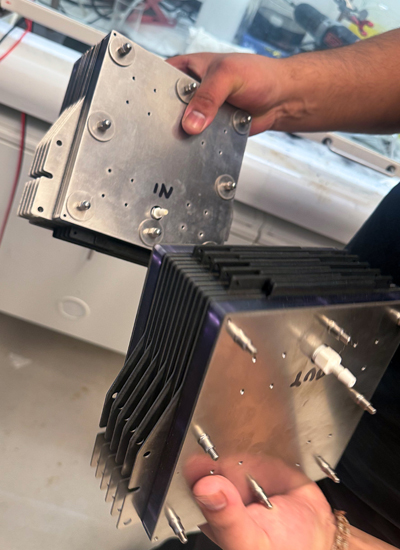

The KTH researchers’ method involves dividing the process into two stages with a completely new type of electrolyzer. The patented solution consists of a membrane-free hybrid cell that can alternately produce hydrogen and oxygen. The cell contains a supercapacitor that makes it possible to control which gas is released by reversing the polarity of the cell.

“By completely separating the production of the two gases at different times, we don’t need any membranes or other separation methods to avoid creating dangerous and explosive mixtures of oxygen and hydrogen,” explains Dutta.

Safety is not the only advantage the new technology offers. By avoiding use of a membrane, the new electrolyzer will be simpler and cheaper to manufacture than existing versions. In addition, it works well even with varying power sources. This makes it particularly suitable when electricity used in the process comes from solar and wind power, which provide a variable electricity supply.

“With the help of our solution, it’s possible to produce hydrogen irrespective of whether you have access to large or small amounts of energy,” says Esteban Toledo, a PhD student who developed the technology together with Professor Dutta.

With more precise control of hydrogen production, the technique results in cleaner hydrogen than today’s methods. It is also possible to use the technology in alkaline conditions, which in turn means you do not have to use rare and expensive materials such as platinum for the electrodes.

Scaling the prototype

The technique is already developing the same efficiency levels as existing electrolyzers in terms of how much electricity is required to produce hydrogen gas. The next step is to scale up the prototype and to further improve its efficiency.

“By heating the system, we will probably be able to further reduce energy consumption. And due to the simplicity of our system, we also see no degradation of the electrodes as in other systems. However, we need to do more full-scale trials to really show the benefits to everyone,” says Dutta.

The researchers’ results were recently published in the respected research journal “Science Advances”. The innovation is also being commercialised by the company Caplyzer, supported by KTH Holding and received development support from Sweden’s innovation agency, Vinnova in the Acceleration call for deeptech companies in 2023.

Text: Magnus Trogen Pahlén