How we aim to speed up the automatisation of Swedish industry

KTH Robotics Concept Lab is going to be a platform for the development and testing of new technical concepts in robotics and intelligent machines. The platform will speed up the ongoing automatisation and robotisation of Swedish industry.

Sweden has all the necessary prerequisites to become one of the world's leading countries in automatised production. The technical prerequisites in the form of a well-developed industry and world-leading research in robotics and automatisation are already in place.

However, there is a huge lack of venues where industry and the academic community can meet. There are no physical locations where the concrete needs of industry can meet practical, research-based solutions. KTH Robotics Concept Lab will be a contact area that will increase knowledge and lay the foundation for new, disruptive solutions to concrete problems.

Problem-oriented and outreaching

Unlike previous initiatives, activities at KTH Robotics Concept Lab will be outreaching and will prioritise personal contacts to establish new forms of collaboration. The approach will be problem-oriented and research-based so as to create new, innovative solutions to problems that are preventing growth.

More widespread automatisation of Swedish industry is the way to bring about increased productivity and greater efficiency. There are many areas in the classic manufacturing industry, construction industry and warehouse management that can be further streamlined.

Other examples include the inspection and maintenance of infrastructure such as roads, bridges and tunnels that can be managed by new types of robots. The mining industry has already come a long way with remotely controlled vehicles, but the potential for further automatisation is huge.

Eliminating harmful work tasks

In many industries, there are still many repetitive and harmful work tasks which could be performed by different types of robots. For example, in forestry and agriculture, there are dangerous, laborious tasks that are better suited for smart machines. However, at the moment, there is little knowledge about what is actually possible.

KTH Robotics Concept Lab aims to increase the exchange of knowledge between cutting edge research and everyday industrial production. In addition, this platform will lead to increased collaboration between KTH and industry. This will be a venue for lifelong learning where people from industry can go to update and renew their knowledge. At the same time, new technology and know-how will increase opportunities for Swedish export.

Key persons

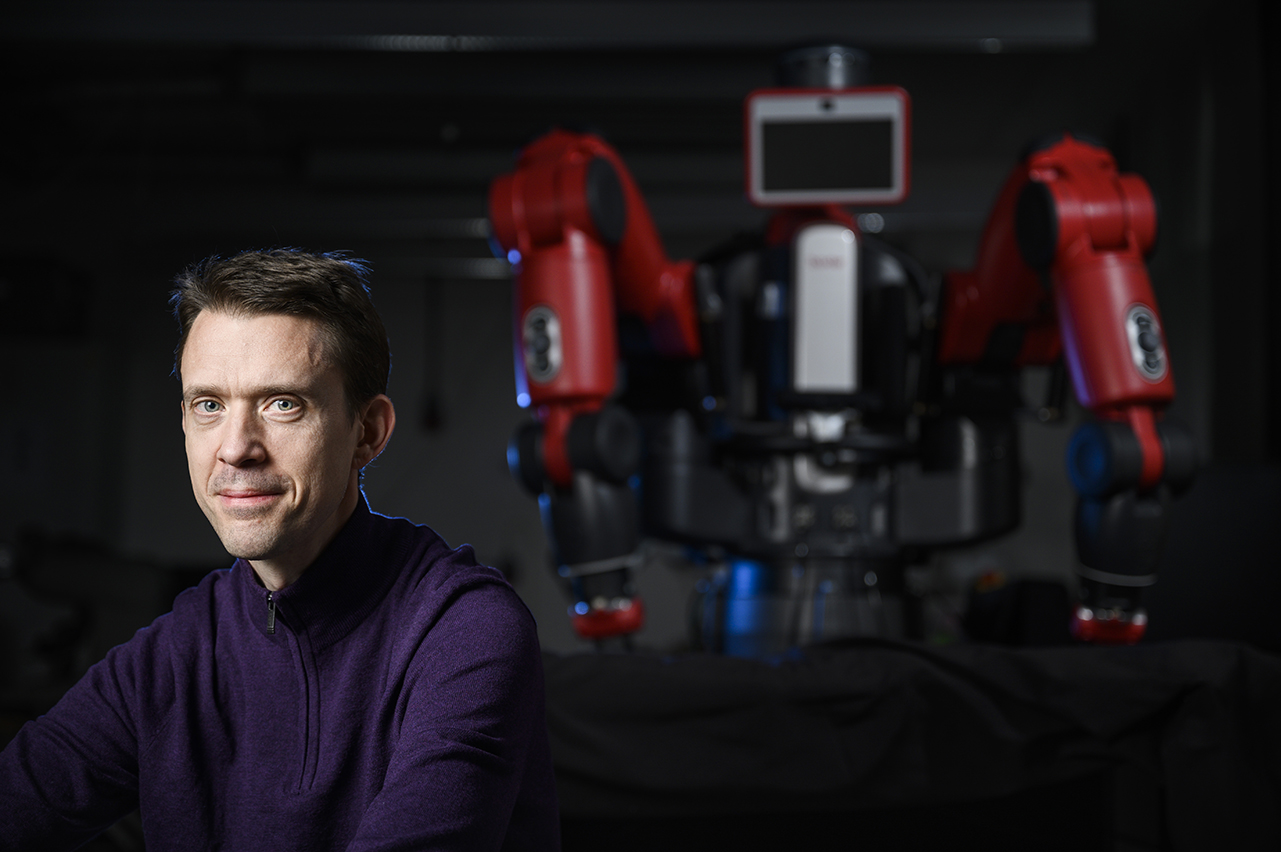

Patric Jensfelt, Professor of Computer Science, specialising in Robotics.

Per Ljunggren, development and project manager with many years of experience from industry in robotics and automation.