Research at Hero-m 2i

The research within Hero-m 2i involves fundamental topics of strategic value for Materials science as well as more applied topics. Our main emphasis is on new theoretical predictive tools, but experimental verification and measurements also play an essential role in the research projects.

The research within the centre spans from materials that are industrially relevant today and have a potential for improvement, e.g. steels and cemented carbides, as well as materials that are expected to become important in the near future, e.g. advanced electronic materials, nano steels and amorphous steels. Although the main emphasis is on new theoretical predictive tools experimental verification and measurements play an essential role.

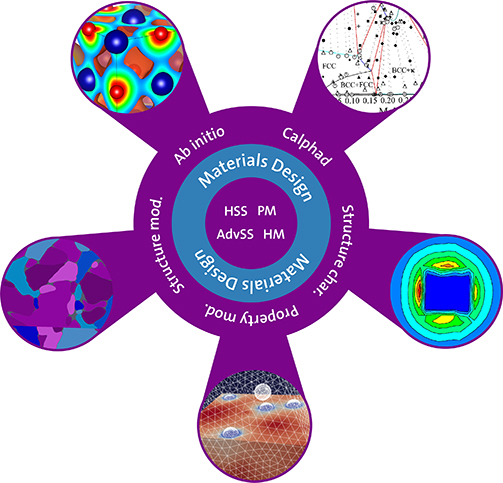

The research within Hero-m 2i is organized in two groups, Materials Design projects and Generic projects.

Generic projects:

- Ab-Initio

- Calphad

- Structure Modelling

- Structure Characterization

- Property Modelling.

Materials Design projects:

- Hard Materials (HM)

- Powder Based Materials (PM)

- High Strength Steels (HSS)

- Advanced Stainless Steels (AdvSS).

The Materials Design projects gather around certain critical aspects within these application areas and the Centre further develops the tools necessary to address these problems. Furthermore, the CMD principle is applied to generate materials innovations and to implement and disseminate the approach to the partners of the competence Centre.

Computational Materials Design, CMD

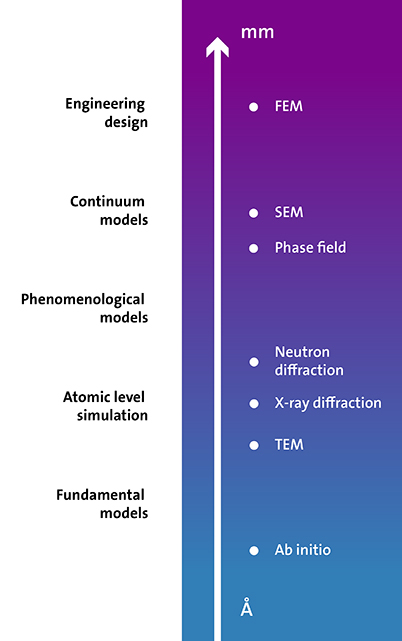

CMD is a new enabling technology dedicated towards the design of a material that meets the performance requirements in a given application. The technology is based on predictive computational modelling of the materials processing-structure-property-performance relations. These relations are explicit in the bottom-up direction, i.e. it is in principle possible to predict the performance given the material composition and processing. However, in the CMD process the top-down approach is adopted, which means that a specific recipe of composition and processing is sought for from the input performance requirements. This is an iterative procedure and the top-down approach is often referred to as the Cohen reciprocity.

Materials modelling have been shown most successful when it is based on the ICME approach, i.e. multi-scale modelling combined with key experiments. This is the approach taken within Hero-m 2i. What is needed for a successful CMD strategy that shifts focus from trial and error to predictive modeling, are different models linking the properties to the structure (translators) and models linking the structure to the processing (creators). Within Hero-m computational tools have been developed to model e.g. structure evolution due to certain treatments, e.g. TC-PRISMA and phase-field models of martensite, bainite, spinodal decomposition, and structure-property relations.

Within Hero-m 2i these models will be implemented in a materials design concept together with development of new translator and creator models to facilitate efficient design. The models can span from semi-empirical to advanced phase-field simulations predicting the structure, coupled to crystal plasticity simulations by FEM of the mechanical response of the structure the full component under various external conditions.