Multidisciplinary Design and Optimization

Lightweight design is often characterized by a need to resolve functional conflicts. As a structure becomes more optimized against a set of objectives, other requirements that were previously either unknown or intrinsically fulfilled might have to be addressed. This is relevant for any lightweight structure where weight is of great importance and this is addressed in several of our activities.

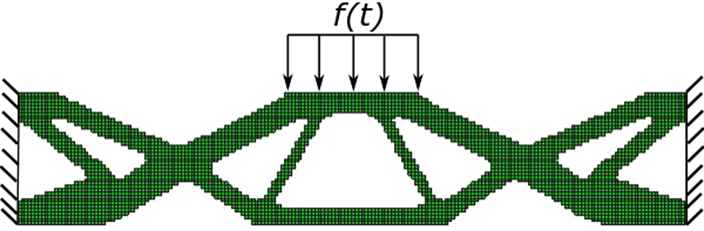

Topologyoptimisiation of structures with static and dynamic constraints

The conflict between lightweight structures and dynamic performance is a classic topic, here the problem is approached by topology optimization. A structure subjected to a harmonically varying load is minimized for mass while retaining required stiffness, both static and dynamic. The problem formulation imposes several challenges and results can be quite different depending on the influence of the requirements. The resonance frequencies of the structure will affect the solutions and as the optimization progresses, the natural frequency will change and this can have a great influence on the final solution.

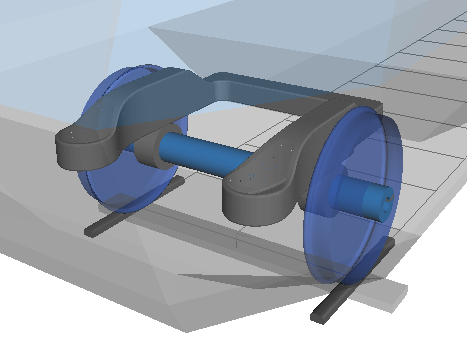

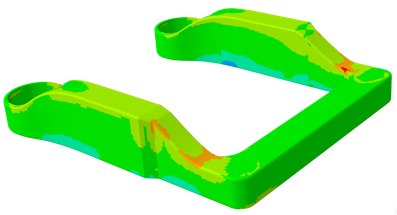

Design of flexible composite single axle running gear frame

One of the heaviest components on a railway vehicle is the running gear. The running gear is a complex mechanical system with requirements on the rolling performance, safety, comfort, dynamic insulation and other. It also provides the suspension of the car body. One component of the running gear is typically a frame connecting the axles to the rest of the vehicle, this is traditionally arranged in the form of a bogie. Using composite materials in the frame can allow for a more interactive design of the running gear where the frame itself provides some suspension action. In the example below the structure of a composite frame for a single axle running gear has been optimized multi-functionally to act as an anti-roll bar with input from analyses in structural mechanics, vehicle dynamics and incorporating an active suspension system. This has the potential to reduce the vehicle weight as well as the running resistance contributing to a reduced energy consumption.

Technical cost modelling

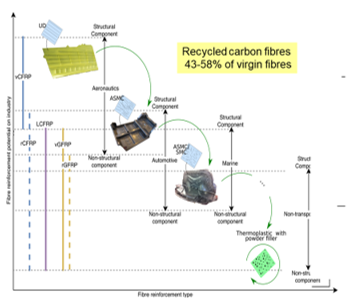

Technical cost modelling frameworks are developed to enable studying true design for circularity towards meeting the target on sustainability.

Designs for circularity and composites recycling

Novel methods for recovery of fibre reinforcement from carbon/epoxy thermoset prepregs are implemented into the design framework. However, different methods for mechanical recycling of composite material are also experimentally evaluated

Novel methods for recovery of fibre reinforcement from carbon/epoxy thermoset prepregs are implemented into the design framework. However, different methods for mechanical recycling of composite material are also experimentally evaluated