Structural Integrity and durability of lightweight structures

This path of research relates to design and fabrication of welded high strength steel lightweight structures. The current research emphasizes, but not limited to, topics related to development of new generation of fatigue design methodology, digitalization of quality assurance in production and computational weld mechanics. An additional path of research is characterization and fatigue of CFRP materials and structures for automotive applications.

Advances in computational weld mechanic

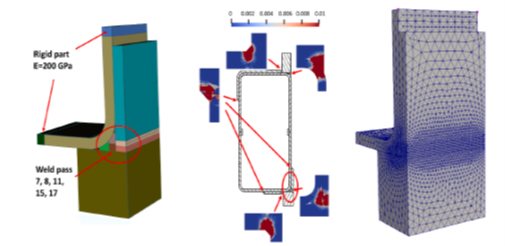

Welding is the most common joining technique used to manufacture large structures such as cranes, wheel loaders, and trucks, etc. Owing to the shrinkage of melted metal, additional distortions and residual stresses are induced which have significant influence on structural functionality and fatigue strength. In this scope of research advanced computational weld mechanics FE frameworks are developed for fast and reliable estimation of residual stresses and distortion in large complex structures for more accurate structural integrity assessment.

FE welding simulation of large welded beam structure in a crane application.

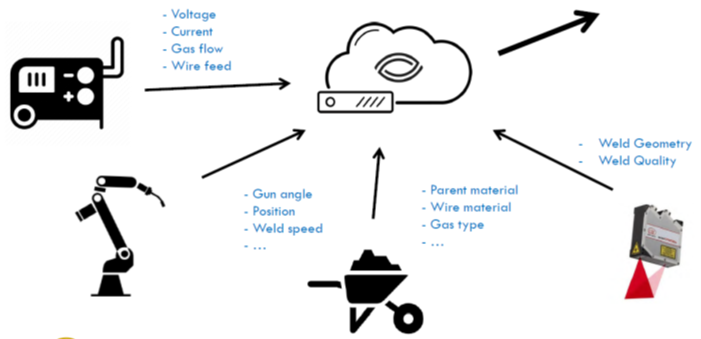

Digitized weld quality assurance – towards industry 4.0

Winteria® is a patented digitized quality assurance system for welding production which today is finding its way broadly into the industry. The research and development behind this quality assurance system is originated from the Lightweight Structures group.

Digitized quality assurance has shown to result in unique opportunities to produce optimized lightweight high strength steel welded structures including accurate structural integrity assessment. The current research topics are AI and deep learning on a systems level in different steps of product development and production processes.

Digitized weld quality assurance of welded structures; a schematic view of current research activities focusing on deep learning

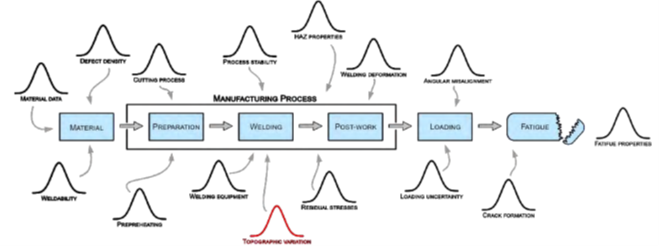

Uncertainties and fatigue – toward new methodologies for design

New and unique opportunities for more accurate design arises with digitized quality assurance systems which produces big data and enables deep learning. Within this track of research new and novel probabilistic fatigue design methods are developed to cover all known uncertainties, from “cradle to grave”, which could possibly influence the structural performance and durability of welded lightweight structures.

Schematic representation of process parameters and their uncertainties.

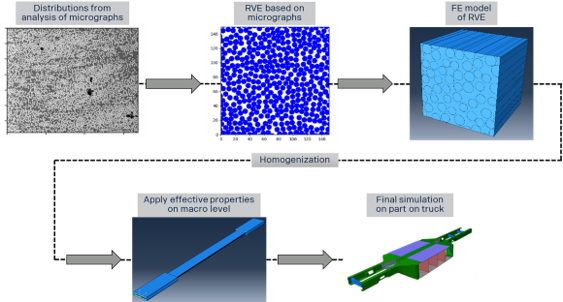

Fatigue design of CFRP for commercial vehicles

Composite materials for structural applications are rarely found in the commercial vehicle industry today. There are great advantages with CFRP structurally advanced materials enabling lightweight design and modularization for commercial vehicles. However, besides the challenges with recycling of CFRP materials there are limited methodologies for fatigue design on structural level. The aim of the research is to develop methodologies to assess fatigue of CFRP for commercial vehicle structures.

Multiscale modeling of CFRP material, from micrographs, representative volume element (RVE) to structural level.