Fabricating functional multicomponent stacks based on nanopaper and spray‐coating

Research description

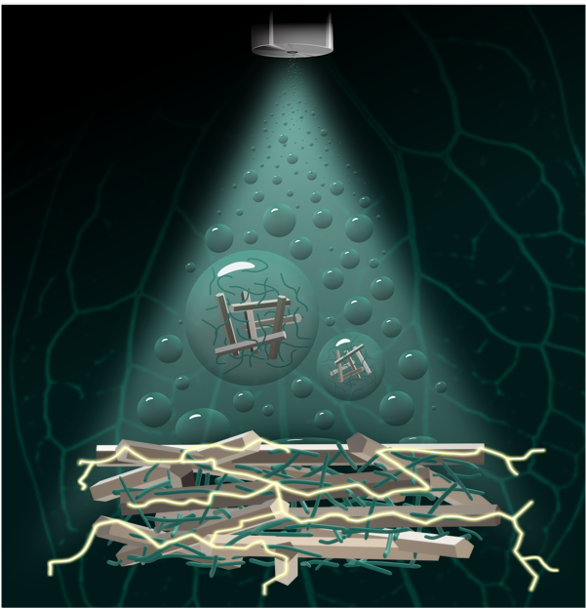

As we move away from fossil fuels, the fabrication of sustainable electrical devices will be an important challenge in the future. Especially the interest in conductive materials, which are thin, transparent, and flexible is growing as they can be used in handy gadgets like wearable sensors, batteries or electronic clothing. Nanocomposites, consisting of e.g.conductive nanoparticles like silver nanowires (AgNWs) and a sustainable matrix material like cellulose nanofibrils (CNF), can meet these requirements. Furthermore, the fabrication of these nanocomposites should be as easy, fast, and sustainable as possible to make them attractive for the industry. By using spray deposition as a fast and easy-to-implement technique, it is possible to fabricate thin, homogeneous, and smooth films fast and on a large scale. Specifically, applied sequentially, roll-to-roll spraying becomes an attractive route for large-scale industrial production. By spraying functional materials layer-by-layer, nanostructured thin films and layered multi-component systems like organic solar cells can be fabricated.