Materials Design project: AM / Powder Based Materials

Design of powders for high-performance steel components produced by AM.

Over the last 5 years additive manufacturing (AM) has become a well-known technique to manufacture components with complex shapes in a reasonably simple way. This has led to a real "hype" worldwide and many universities and companies now have started research and development activities on AM. So far most metallic components made by the AM technique have inferior properties compared to conventionally made components. This is due to a com-bination of porosity, residual stresses and unfavorable microstructures. There are some excep-tions, i.e. some alloys are suitable for AM, e.g. some Ti- and Ni-base alloys.

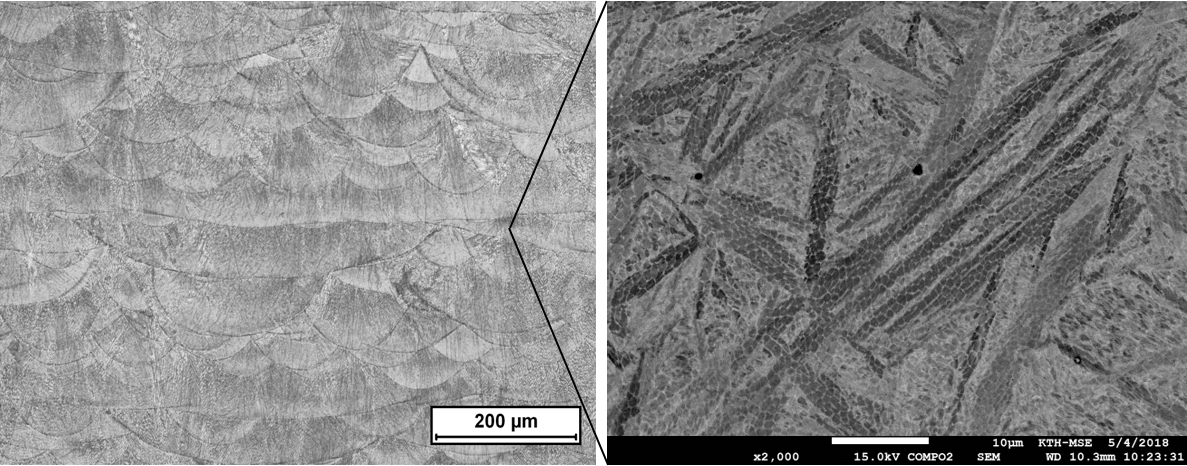

The AM technique involves a very severe processing of the alloys and special care must be taken when developing alloys for AM. The present project has a materials focus and is devoted towards the development of high-performance components from steel powders by AM and has a material focus. The work will involve the structural development as well as development of porosity, residual stresses and properties.