Materials Design project: Hard Materials

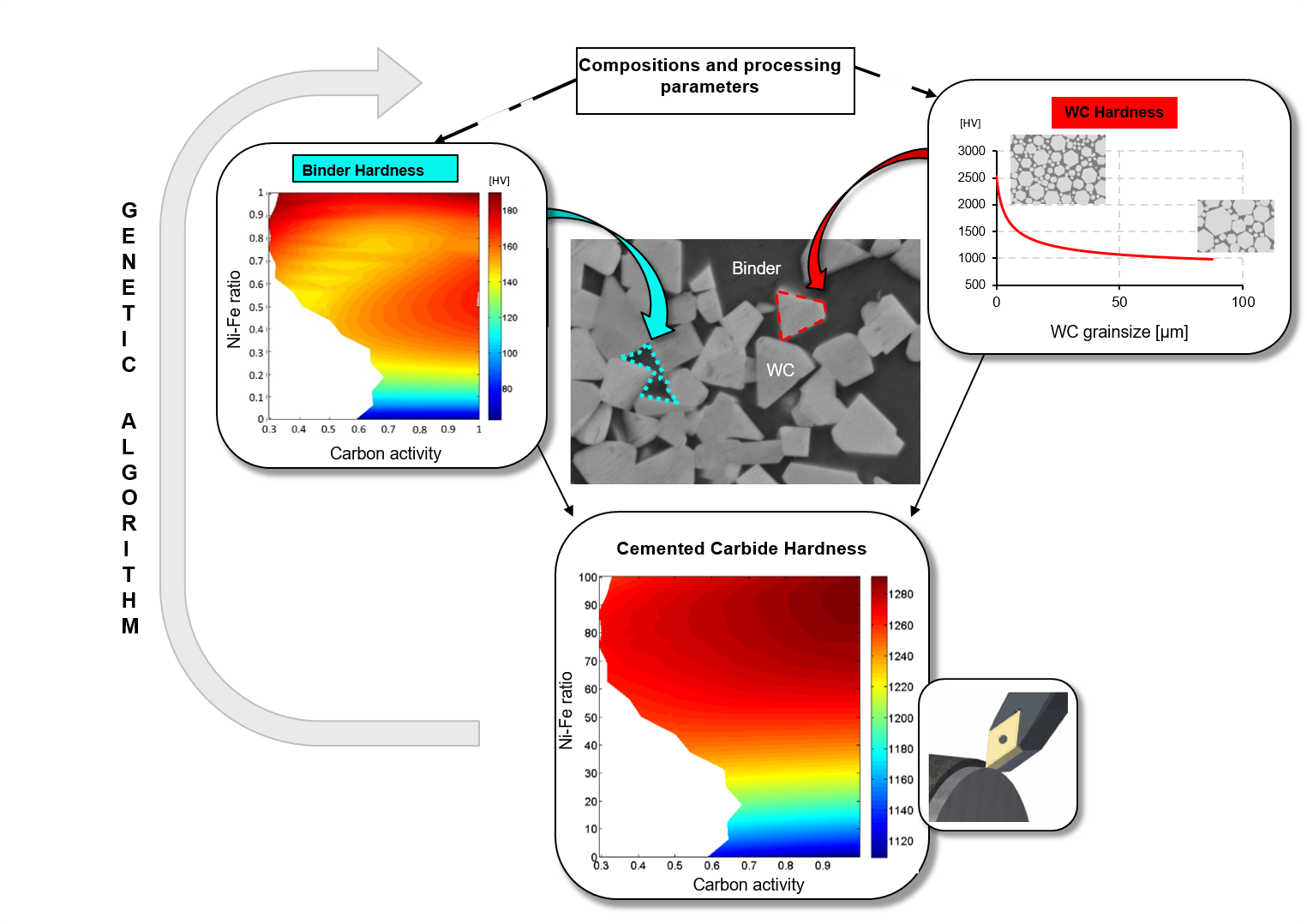

This project addresses the next generation of carbide-based systems for high-performance tools used in metal cutting, drilling and rock drilling. In this project the efforts are be directed towards design of hard metals without Co and W.

At present the hard metals used for high-performance metal cutting, drilling and rock drilling are based on cemented carbides. Such materials consist of hard carbide phases, mainly WC and often different cubic carbides such as TiC embedded in a ductile metallic binder usually Co.

However, Co and W have a number of drawbacks; both elements are regarded as critical raw materials and new European regulations regarding the health impact of Co may call for solutions with alternative binder materials. Besides, Co has some deficiencies also from an engineering point of view as the binder undergoes a gradual softening and the hardness drops from initially high values to much lower values during machining operation at ca 800 °C. There are thus several good reasons to design a new type of hard metal without Co and W.

In general a broad range of computational tools and models are needed for developing a hard metal using the CMD approach. Many are available, but for investigating new systems the models, which are operating at different length scales, may have to be developed, modified or at least it is necessary to know their validity. It needs to fulfill a number of requirements to develop the necessary linkage-tools to tailor the materials. The work will include thermodynamic and kinetic calculations and calculations of mechanical properties.

Cutting tools are often coated and for the cutting tool design the gradient formation of a ductile surface layer is crucial to improve the materials behavior in interplay between a coating and the bulk material. Kinetic information is required for modelling this diffusion based process, but due to experimental difficulties in measuring the diffusion coefficients accurate kinetic description is often not available. Ab-initio molecular dynamical (AIMD) simulations can be performed to overcome those limitations. The diffusion coefficients implemented into DICTRA, are key design parameters for the creator between processing and structure.