Production Systems and Automation

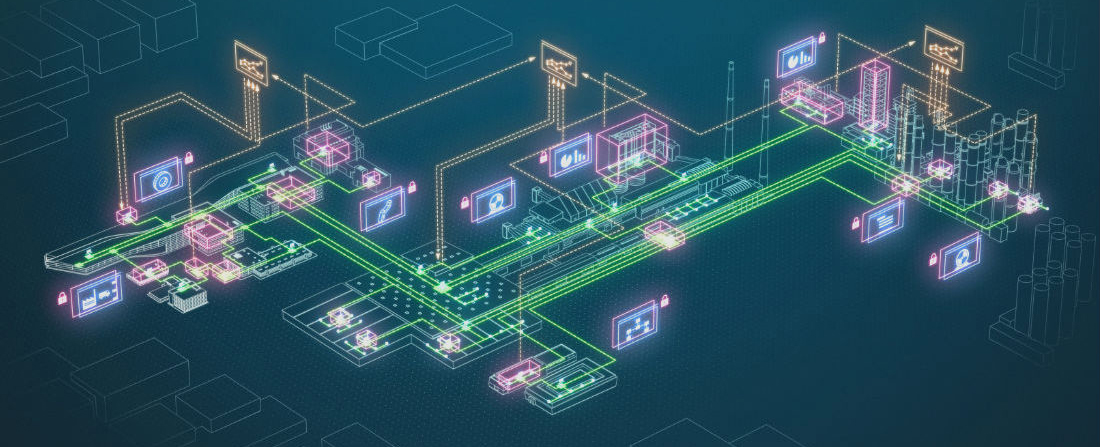

Research in the unit of Production Systems and Automation focuses on both fundamental research and industrial applications in the area of sustainable manufacturing and production systems.

About the research

Our research activities cover the spectrum from machine-level adaptive control to enterprise-level manufacturing management. Sustainability concerns are addressed from environmental, social and economic perspectives along the lifecycle of products and during production. Adaptability is another target of our solutions to address dynamism and uncertainty on manufacturing shop floors, by applying real-time manufacturing intelligence for closed-loop decision making.

This research is conducted in close collaboration with manufacturing companies and their development of production systems, and involves identifying development processes and various influencing factors. In a number of research projects together with companies and other production researchers, new production systems and methods to increase the efficiency of production have been studied.

Research Areas

Activities

In the era of Industry 4.0 towards smart manufacturing, our research activities include, but are not limited to:

- Human-Robot Collaboration

- Human-Cyber-Physical Production Systems

- Machine Learning in Assembly

- Big Data Analytics in Process Planning/Scheduling

- Cloud Manufacturing

- Condition-Based Predictive Maintenance

- Model-Based Sensor-Driven Remote Monitoring and Control

- Brain Robotics for Human-Centred Production.