2025 Mechatronics HK Grand Finale

Each year, students from the Advanced Mechatronics course are tasked with building a prototype as their final project. The course culminates in a presentation and demonstration session, where students showcase their final designs. This year's event took place on 8, December.

This year’s projects included a wide variety of innovative ideas: a joystick-operated excavator bucket, an autonomous rover capable of performing a complete U-turn without human input, a semi-automatic machine designed to improve the manufacturing of strings for violin, viola, cello, and keyed fiddle, a standardized method for assessing forest fire risk, and a robot dog to mention few. Some of the prototypes are being designed in collaboration with industry and will be used for specific purposes. This year’s projects partnered with Volvo Construction Equipment, The Swedish Civil Contingencies Agency (MSB), RISE, Research Institutes of Sweden and a family-owned company manufacturing strings to instruments.

We visited the demonstration area to learn more.

In one of the labrooms we found Erik Gelfgren, Oscar Held, and Hataipat Sirirattanaphan fine-tuning their machine, the Rapid-ZD Tester 2.0, which is a device designed for the paper packaging industry. The machine aims to capture detailed data on material properties, helping to understand what is required to achieve high-quality printing at industrial speeds.

“The Rapid-ZD Tester 2.0 is a high-precision machine that measures material response to rapid impulses, capturing data at 1 million samples per second. Its purpose is to help researchers understand the printability of paperboard packaging, and we look forward to seeing it put to practical use,” says Erik Gelfgren.

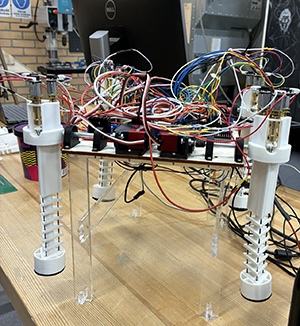

In the next room, we met Joackim Knälmann and Philip Ågren Jahnsson, who, along with their teammates, had explored new applications for soft robotics. Soft robotics replaces rigid structures and heavy joints with flexible materials that can bend and stretch. Their robot dog features deformable legs actuated by twisted wires that contract and relax, allowing the robot to move smoothly.

Joackim explained that the project was both exciting and challenging. The task was to create a soft version of an existing robot dog. Once all of the individual components were designed, the remaining challenge was to assemble everything together, which turned out to be trickier than expected. The robot dog is controlled by two small onboard computers that coordinate

the movements via connected wires. Joachim was also interviewed by SVT Local news, you can find link to the news segment further down on this site.

Niklas Nyberg and his group have collaborated with Volvo Construction Equipment to introduce a new method for controlling excavators, replacing the traditional hydraulic levers with a handheld controller that directly manages the bucket’s position.

"Traditional hydraulic control requires skills, especially for smooth or straight-line movements. For an inexperienced operator, even basic tasks can be difficult. With our position-based control system, the operator simply moves the controller in the desired direction, and the excavator automatically calculates the hydraulic movements needed to achieve the motion. This system is especially useful when preparing roads for asphalt laying,” explains Niklas.

We also spoke with Jessica and Niclas Fjölel, third-generation entrepreneurs who attended the event to explore a new machine designed for string manufacturing. The semi-automatic string-making machine improves precision and repeatability by combining mechanics, electronics, pneumatics, and control systems, focusing on monitoring and controlling string tension throughout production. This method substantially enhances the previous production process, where tension had to be assessed manually by the operator.

"We are impressed by the mechatronics students’ innovation and dedication. The Awesome String Winding Machine will have a significant contribution to our production. If we had designed and built the machine ourselves, it would have taken years. Being part of this project has been a great experience", says Jessica.

The mechatronics students’ work not only showcases technical skill and problem-solving ability—it also offers a glimpse into the future. The students demonstrate how modern mechatronics can transform industrial processes, streamline work, and open the door to entirely new technological applications. The next opportunity will be at the end of the course next year.

The event was visited by Swedish Television, SVT Local news. Check out the segment (scroll to 06:47 in the program).

Read more about All projects (pdf 1.3 MB)

Text and photo: Rita Nõu