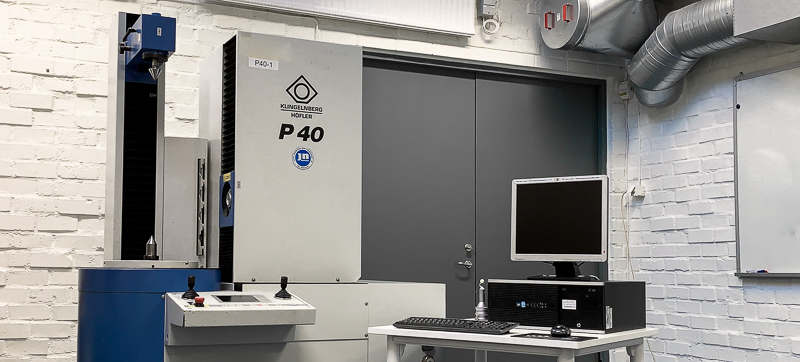

Installation of a Klingelnberg P40 precision measuring center

This week we received and installed a Klingelnberg P40 precision measuring center for gear inspection at PMH Application Lab.

The P40 allows to inspect the geometry of several gear types and gear cutting tools until a maximum diameter of 400 mm according to the latest industrial standards. The repeatability for measuring profile and helix deviations of gear flanks is better than 0.5 µm. This precision enables PMH to perform in particular research and development at the forefront of manufacturing of gears for e-drives, which require much tighter tolerances than gears for conventional transmissions. The P40 will also be a valuable addition in our education activities in order to convey practical experience in gear inspection to KTH’s students and professionals from industry.

The PMH Application Lab thanks in particular Scania for donating the measuring machine to KTH and by this strengthening the pre-requisites for PMH Application Lab to support the Swedish powertrain industry. Furthermore, we would like to thank the companies Klingelnberg and Tunga Lyft as well as the involved personnel from KTH for their support in transport, installation and the start of operations.

For more information, contact: