National testbed for smart production

Background

The purpose of the National Test Bed Smart Production is to increase the availability of existing test beds in the production area. The project will invest in the following: digital models, connectivity and new business models. The project will coordinate Chalmers Smart Industry Lab as well as PMH Application Lab at KTH, and in addition: Production2030's ten test bed projects. The objectives are to increase the use of digital technologies in Swedish manufacturing companies and thereby increase competitiveness.

Focus of PMH Application Lab in the project

The predominant focus of existing testbeds and competence centers is currently on solutions for individual locations. The PMH Application Lab and its partners Sandvik Coromant and Scania work on test cases from the powertrain industry. Compared to other testbeds a value chain which is relevant for cross location aspects for the discrete component manufacturing is in focus and PMH thus develops a unique test and validation platform for developments in industry 4.0 and smart production developments – especially for small and medium sized companies in close cooperation with OEMs as well as other, international acting, companies.

The challenge

Facing this technical background the research questions on the cross location handling of data below shall be addressed. The testbed shall give the possibility to evaluate on the one side the added value of provided data and on the other side at the same time the possibilities and risks concerning data security in a complex value chain environment.

The research questions below will be addressed in the PMH testbed:

- Can a digital cross-location infrastructure in combination with suitable sensors provide the current technical condition of a component in a cross-location value chain independent from the location of the process owner by means of a digital twin?

- Can model-based data analytic tools, which are provided in a cloud system, enrich the information in the digital twin by means of simulation tools in a way that a close to reality image of the component is generated?

- Is it possible to properly evaluate the current quality state and to extrapolate the final quality of a component from the data that are stored in a digital twin?

Our solution

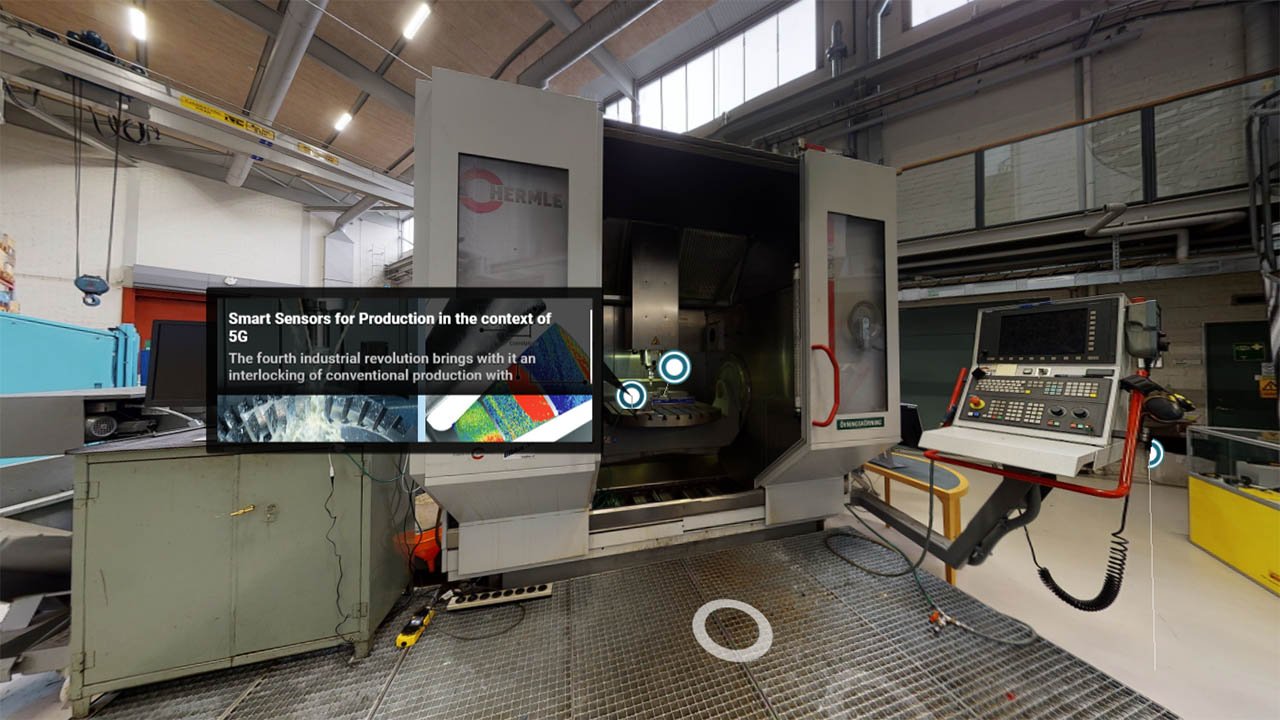

The concept of the PMH testbed is to provide a test and validation platform for cross-location production in powertrain manufacturing. Production systems at different sites are connected by a cloud which is used for data acquisition from respective production systems and storage of data of the produced components in digital twin. In the cloud software tools are performing model-based data analytics to interpret and enrich the data of the digital twin. Furthermore apps in the cloud provide and visualize the data to the process owner independent of his/her location. The different sites in the concept can be the PMH Application Lab at KTH campus – the central node of the testbed – sites of PMH’s partners (e.g. Fraunhofer IPT or Fraunhofer IWU) and industrial partners that would like to test and validate the connection of their sites to a crosslocation production environment. The long-term integration of the sites of Fraunhofer IPT and Fraunhofer IWU is part of an initiative to extend the PMH testbed into a “Swedish-German testbed for smart production”.

Project partners

-

Produktion 2030

-

PMH Application Lab

-

Scania

-

Sandvik

-

Volvo

-

Chalmers Stena Industry Innovation Lab

-

Virtual Manufacturing

-

PdS Vision

Project duration

December 2017 - July 2021