Project: Engineering 3D printed and knitted degradable scaffolds

Project information

Engineering 3D printed and knitted degradable scaffolds (PrintKnit) is financed by Swedish Foundation for Strategic Research.

PrintKnit’s overall purpose is the development of degradable, three- dimensional scaffolds for soft tissue regeneration - combine pliability with mechanical rigidity with the aid of for example 3D printing.

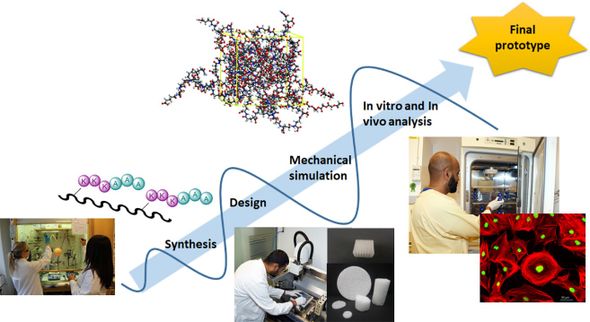

Figure 1. Project scheme.

Figure 2. Interdisciplinary research in PrintKnit project.

The architecture of the scaffolds is designed using hierarchical scales from micro- to millimeter level, to possess pliable, highly porous structures with the ability to control bioactivity, mechanical properties and degradation rate over time. The final aim is achieved by joining different expertise ranging from the design of synthetic polymers, their processing into 3-D structures, subsequent cell interaction and mechanical simulation of the material interlinked at all levels.

The central criterion of this project is the choice of the material from which the scaffold, with a defined architecture, should be fabricated. In the core of this project lies the material properties of the polymeric scaffold and the interaction with cells and surrounding tissue. Aliphatic polyesters and polycarbonates are of interest in manufacturing of medical devices due to their (in many applications) biocompatibility and degradability. Using these synthetic polymers allow for the ability to tailor the chemical structure and composition, leading to high control of the degradation rates and properties of the material.

Untreated aliphatic polyesters have limitations in terms of cell-material interactions. The interaction on the cellular level is in this project designed through synthesis and functionalization of suitable degradable polymers. Parallel to the development of the scaffold the biological interactions are evaluated through in vitro studies and sequentially by in vivo studies.

Figure 3. 3D printed architecture scaled into three different sizes (top) and 3D printed strands on a textile (bottom).

To reach the aim to optimize the design, we also focus on material mechanics simulation. The design process will for example integrate a biomechanical assessment of scaffolds using Representative Volume Element (RVE) simulations of the individual 3D designs.

Once the mechanical and chemical characterization of the scaffolds will be done, in vitro cell studies will be carried out. Furthermore, in vivo animal model studies will be implemented to check the success of the implantable scaffolds.

Publications

-

H. Liu, S. Jain, A. Ahlinder, T. Fuoco, T.C. Gasser, A. Finne-Wistrand,”Pliable, Scalable, and Degradable Scaffolds with Varying Spatial Stiffness and Tunable Compressive Modulus Produced by Adopting a Modular Design Strategy at the Macrolevel” ACS Polym. Au (2021), https://doi.org/10.1021/acspolymersau.1c00013

-

S. Jain, M.A. Yassin, T. Fuoco, S. Mohamed-Ahmed, H. Vindenes, K. Mustafa, A. Finne-Wistrand,” Understanding of how the properties of medical grade lactide based copolymer scaffolds influence adipose tissue regeneration: Sterilization and a systematic in vitro assessment” Mater. Sci. Eng. C. (2021), 124, 112020, DOI: https://doi.org/10.1016/j.msec.2021.112020

-

T. Fuoco, M. Cuartero, M. Parrilla, J. García-Guzmán, G. A Crespo, A. Finne-Wistrand, “Capturing the Real-Time Hydrolytic Degradation of a Library of Biomedical Polymers by Combining Traditional Assessment and Electrochemical Sensors” Biomacromolecules (2021), 22(2), 949-960, DOI: https://dx.doi.org/10.1021/acs.biomac.0c01621

-

M. Rizwan, A.Fokina, T. Kivijärvi, M. Ogawa, M. Kufleitner, O. Laselva, L.J. Smith, C.E. Bear, S. Ogawa, G. Keller, M.S. Shoichet, “ Photochemically Activated Notch Signaling Hydrogel Preferentially Differentiates Human Derived Hepatoblasts to Cholangiocytes” Adv. Funct. Mater., (2020), 2006116, https://doi.org/10.1002/adfm.20200611

-

S. Jain, M.A. Yassin, T. Fuoco, H. Liu, S. Mohamed-Ahmed, K. Mustafa, A. Finne-Wistrand, “Engineering 3D Degradable, Pliable Scaffolds Toward Adipose Tissue Regeneration; Optimized Printability, Simulations and Surface Modification” J. Tissue Eng., (2020), 11, 1–17 , DOI: https://doi.org/10.1177/2041731420954316

-

A. Ahlinder, S. Charlon, T. Fuoco, J. Soulestin, A. Finne-Wistrand, “Minimise thermo-mechanical batch variations when processing medical grade lactide based copolymers in additive manufacturing” Polym. Degrad. Stab. (2020), 109372, DOI: https://doi.org/10.1016/j.polymdegradstab.2020.109372

-

T. Fuoco, T. Nguyen, T. Kivijärvi, A. Finne-Wistrand, “Organocatalytic strategy to telechelic oligo(ε-caprolactone-co-p-dioxanone): photocurable macromonomers for polyester networks” Eur. Polym. J. (2020), 141, 110098, DOI: https://doi.org/10.1016/j.eurpolymj.2020.110098

-

T. Kivijärvi, D. Pappalardo, P. Olsen, A. Finne-Wistrand, ”Inclusion of isolated alpha-amino acids along the polylactide chain through organocatalytic ring-opening copolymerization” Eur. Polym. J. (2020), 131, 109703, DOI: https://doi.org/10.1016/j.eurpolymj.2020.109703

-

T. Fuoco, RA. Almas, A. Finne-Wistrand, “Multipurpose degradable physical adhesive based on poly(D,L-lactide-co-trimethylene carbonate)” Macromol. Chem. Phys., (2020), 221, 2000034, DOI: https://doi.org/10.1002/macp.202000034

-

H. Liu, A. Ahlinder, M. A. Yassin, A. Finne-Wistrand, T. C. Gasser, “Computational and experimental characterization of 3D-printed PCL structures toward the design of soft biological tissue scaffolds” Mater. Design, (2020), 188, 108488, DOI: https://doi.org/10.1016/j.matdes.2020.108488

-

T. Fuoco, A. Ahlinder, S. Jain, K. Mustafa, A. Finne-Wistrand, “Poly(ε-caprolactone-co-p-dioxanone): a Degradable and Printable Copolymer for Pliable 3D Scaffolds Fabrication toward Adipose Tissue Regeneration” Biomacromolecules, (2020), 21(1), 188-198, DOI: https://doi.org/10.1021/acs.biomac.9b01126

-

A. Ahlinder, T. Fuoco, A. Morales-López, M.A. Yassin, K. Mustafa, A. Finne-Wistrand, “Nondegradative additive manufacturing of medical grade copolyesters of high molecular weight and with varied elastic response” J. Appl. Polym. Sci., (2020), 137 (15), 48550, DOI: https://doi.org/10.1002/app.48550

-

S. Jain, T. Fuoco, M. A. Yassin, K. Mustafa, A. Finne-Wistrand, “Printability and critical insight into polymer properties during direct- extrusion based 3D printing of medical grade polylactide and copolyesters” Biomacromolecules, (2020), 21(2), 388-396. DOI: https://doi.org/10.1021/acs.biomac.9b01112

-

T. Fuoco, A. Finne-Wistrand, “Enhancing the properties of poly(e-caprolactone) by simple and effective random copolymerization of e-caprolactone with p-dioxanone” Biomacromolecules, (2019), 20 (8), 3171-3180. DOI: https://doi.org/10.1021/acs.biomac.9b00745

-

M. A. Yassin, T. Fuoco, S. Mohamed-Ahmed, K. Mustafa, A. Finne-Wistrand, “3‐Dimensional and porous RGDC-functionalized polyester based scaffolds as a niche to induce osteogenic differentiation of human bone marrow stem cells” Macromol Biosci. (2019), 19 (6), e190004, DOI: https://doi.org/10.1002/mabi.201900049

-

T. Fuoco, T. Mathisen, A. Finne-Wistrand, ”Minimizing the time gap between service lifetime and complete resorption of degradable melt-spun multifilament fibers” Polym. Degrad. Stab., (2019), 163, 43-51, DOI: https://doi.org/10.1016/j.polymdegradstab.2019.02.026

-

T. Fuoco, T. Mathisen, A. Finne-Wistrand, ”Poly(l-lactide) and Poly(l-lactide-co-trimethylene carbonate) Melt-Spun Fibers: Structure–Processing–Properties Relationship” Biomacromolecules, (2019), 20(3), 1346-1361. DOI: https://doi.org/10.1021/acs.biomac.8b01739

-

A. Ahlinder, T. Fuoco, A. Finne-Wistrand,” Medical grade polylactide, copolyesters and polydioxanone: Rheological properties and melt stability” Polym. Test., (2018), 72, 214-222, DOI: https://doi.org/10.1016/j.polymertesting.2018.10.007

Project leader

Assoc. Prof. Anna Finne-Wistrand (Principle investigator)

Researchers

Assoc. prof. Daniela Pappalardo (Università del Sannio, Italy)

Alvaro Morales Lopez (PhD-student)

Additional participants

Professor Christian Gasser (KTH)

Professor Mikael Hedenqvist (KTH)

Professor Kamal Mustafa (University in Bergen)

Former members

Dr. Mohammed Yassin (Post-Doc)

Dr. Hailong Liu (Post-Doc)

Dr. Tiziana Fuoco (Researcher)

Dr. Astrid Ahlinder

Dr. Shubham Jain