Dan Zenkert

Professor

Details

Researcher

About me

I received both my M.Sc. (Aeronautics) and Ph.D. (Lightweight structures) from Kungliga Tekniska Högskolan (KTH) in Stockholm, Sweden. I became docent (D.Sc.) in 1996, associate professor in 1998 and full professor in 2001.

I work with mechanics of composite materials with a special focus on multifunctional composites. This includes carbon fibre composites for energy storage (structural battery composites), composites that can change shape (shape-morphing composites), composites with integrated sensing and composites that can be used for energy harvesting. I do this in close collaboration with colleagues at Electrochemistry and Polymer chemistry. Some more information on my research on multifunctional composite materials are given below.

I teach lightweight structures and mechanics of composite materials.

I was born 1961 in Stockholm, Sweden. I remain living in Stockholm now more quitely since my three sons now are adults and have moved away. Apart from working at KTH I coach basketball in the local basketball club once a week. In summer time I enjoy riding my motorcycle (Triumph Legend) but my real passion in life is fly-fishing for trout, something I do every summer in the northern parts of the Scandinavian range.

Multi-functional composites

This path of research relates to carbon fibre composites which are in some way electrochemically active that are structurally high performing and at the same time can be used for energy storage, sensing, shape morphing and energy harvesting.

Structural composite batteries

The idea behind this research is to combine a high-performance carbon fibre composite material with inherent energy storage like a Li-ion battery. By having two distinctly different functions in the material itself it is envisioned that substantial mass savings are possible on systems level since the material both carries structural loads and stores electrical energy.

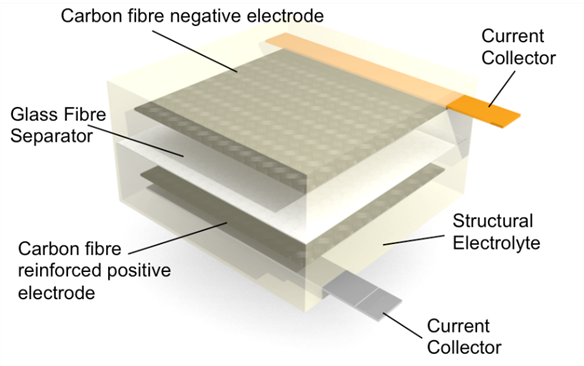

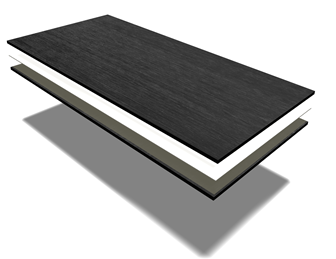

Schematic of a laminated structural battery. The negative electrode is a carbon fibre layer which is separated from the positive electrode consisting of Li-metal oxide coated carbon fibres. The stack is then impregnated with a structural battery electrolyte, a matrix that can both transfer mechanical loads and conduct Li-ions, creating a carbon fibre laminate with inherent energy storage.

Sensing

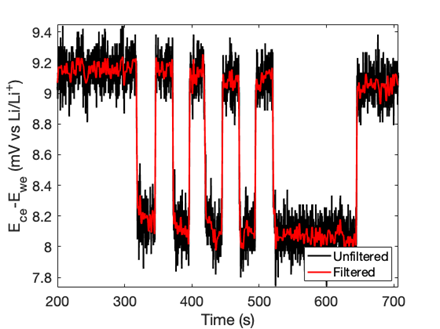

Carbon fibres become piezo-electrochemical when intercalated with Li-ions. This manifests itself as coupling between the electrical potential between the carbon fibre electrode and its counter electrode when mechanical loads are applied, a strain-voltage coupling. Mechanical loads cause the cell voltage to change which can be used to sense the load on the carbon fibre composite.

Voltage change between two Li-intercalated carbon fibre layers when bending strains are applied. (see video:https://play.kth.se/media/RP12_OCPfingerH264/0_8y7o568q)

Shape-morphing carbon fibre composites

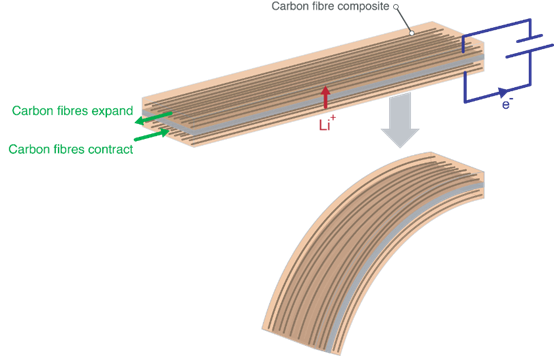

Carbon fibres expand when being intercalated with Li-ions, and contract during deintercalation. Using this effect one can apply a small current or voltage to make a stiff carbon fibre composite laminate change its shape.

A shape morphing carbon composite laminate created by applying a low electrical potential (<1.5V) between two carbon fibre layers causing one layer to expand and the other to contract. (see video:https://play.kth.se/media/Movie+S1/0_5ntruhqj)

Energy harvesting

By combining the effects of carbon fibre expansion/contraction of carbon fibres and the strain-voltage coupling it is possible to convert mechanical work to electrical power making it possible to make a carbon fibre laminate that can harvest energy.

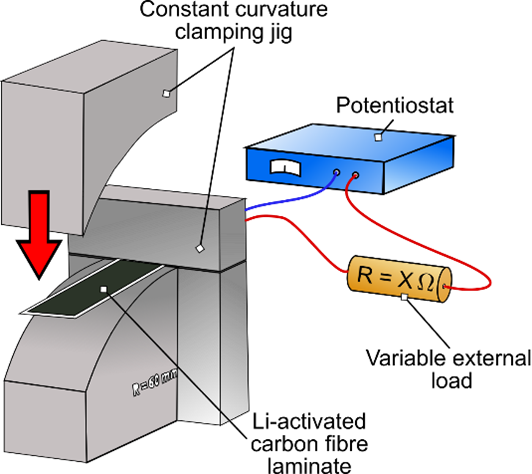

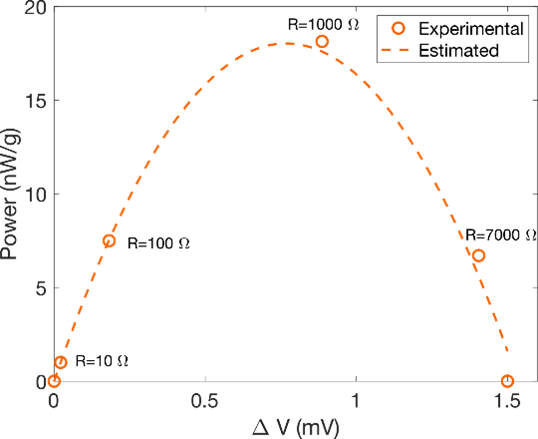

When the carbon fibre laminate is bent a current will run through an external resistor producing electrical power (top). This is thanks to the strain-voltage response caused by the bending of the laminate. Depending on the resistance of the external electrical load different amounts of electrical power will be generated (bottom).

Courses

Degree Project in Lightweight Structures, Second Cycle (SD241X), examiner

Fibre Composites - Analysis and Design (SD2413), teacher, course responsible, examiner

Lightweight Structures and FEM (SD2411), teacher

Vehicle Engineering (SD1002), teacher