ICME on Precipitation

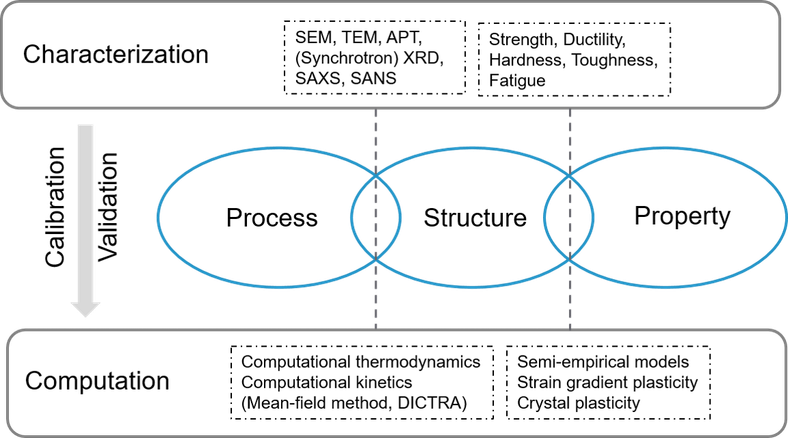

Integrated Computational Materials Engineering (ICME) is built on the principle of linking materials processing, structure, properties, and performance through structure models, property models and performance models. It aims to accelerate materials development/design and optimize product performance.

Figure 1. Integrated Computational Materials Engineering (ICME) framework for precipitation-strengthened martensitic steels.

An ICME framework on precipitaion has been developed based on Cu precipitation in 15-5 PH maraging stainless steel:

- Cu precipitation kinetics using the Langer-Schwartz-Kampmann-Wagner approach coupled with CALPHAD thermodynamic and kinetic databases (tao-zhou-et-al-2018.pdf)(ze-sheng-et-al-2021.pdf) was calibrated by quantitative characterization of Cu precipitates including information of structure, size, volume fraction, number density and chemical composition as a function of ageing conditions measured using TEM (tao-zhou-et-al-2018.pdf), APT (ze-sheng-et-al-2021.pdf) and in situ SANS (tao-zhou-et-al-2022_2.pdf).

- Except for precipitation, models for other martensite microstructure characteristics like effective grain size and dislocation density were also calibrated by experiments, where the dislocation density was quantified using the modified Williamson-Hall and Warren-Averbach method (tao-zhou-et-al-2019.pdf) through analyzing the peak broadening of XRD data. The strain heterogeneity of the martensite matrix were modelled using a dislocation density-based crystal plasticity model (tim-fischer-et-al-2024.pdf).

- With regards to property modelling, yield strength of the material as a function of ageing treatment was modelled using semi-empirical models (tao-zhou-et-al-2019.pdf); the Cu precipitation hardening contribution to the stress-strain curves were modelled using an analytical flow stress model based on strain gradient plasticity theory (philip-crona-c-et-al-2022.pdf).