Biorefinery Technology

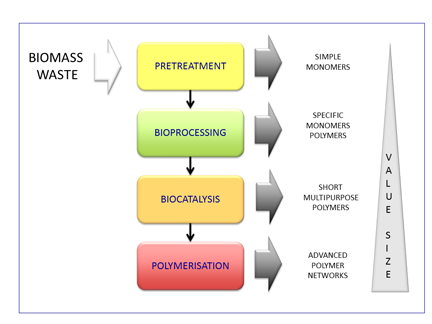

We believe that the successful biorefinery should principally be structured by the same principles as a petroleum refinery.

This means that a biorefinery will have to be able to treat several in-going waste products and produce a range of out-going products - not only of low but also to high value. Furthermore, the structure must be flexible enough to accommodate variation of the input biomass waste sources and fluctuations in customer demand for the refinery products.

The Biorefinery Technology Platforms

The dynamic nature of the refinery will build on a set of flexible technology platforms. With fluctuating biomass waste availability – a change in the start-out platform technology should be able to handle the consistent supply of specific components. With fluctuating customer demand – an adjustment in platform technology should allow the production of a modified or even new range of products. This will require the build of platforms where the same principal technology can be used independent on inputs and need for specific outputs.

The Pretreatment Platform

The goal is to prepare the waste to provide value added components for medium design to maximise productivity in bioprocessing. The biomass waste of present interest is a combination of lignocellulose from wheat processing, waste from quinoa production and liquid food waste. This is due to the inherent broad substance content of these sources and to the interest of recirculation of the particular waste.

Contact

The Bioprocessing Platform

Metabolic engineering is used to design cells for specific purposes. The goal is partly the introduction of new properties of cells for e.g. degradation of waste and/or introduction of new pathways to product formation. The target products are at present selected amino acids, 3-OH butyrate, ectoines and selected polyesters and the organisms E. coli and Halomonas boliviensis.

Contact

The Biocatalysis Platform

From simple monomers such as succinic acid this platform may provide a broad range of products. Of specific interest is to use lipases to produce short polymer resins with tailored reactivity for further processing and functionalization. This activity will develop selective enzyme catalyzed routes toward functional polymer resins in one-pot systems.

Contact

The Polymer Technology Platform

The functional polymer resins can be transferred (cured) into polymer materials. Curing routes where the functional polymers resins are transferred into materials with tailored properties for i.e. coating applications are developed. The research of this platform is performed by the Div. of Coating technology, KTH.

Contact