Optimal flow for maximum performance of geothermal heat pumps

Optimum flow in ground source heat pumps can provide up to 40 percent better performance and corresponding energy savings. The project will investigate the optimisation of the brine flow in geothermal heating plants through modeling and studies of statistical parameters. Validation takes place through experiments in KTH Live in Lab and data from existing facilities.

Background

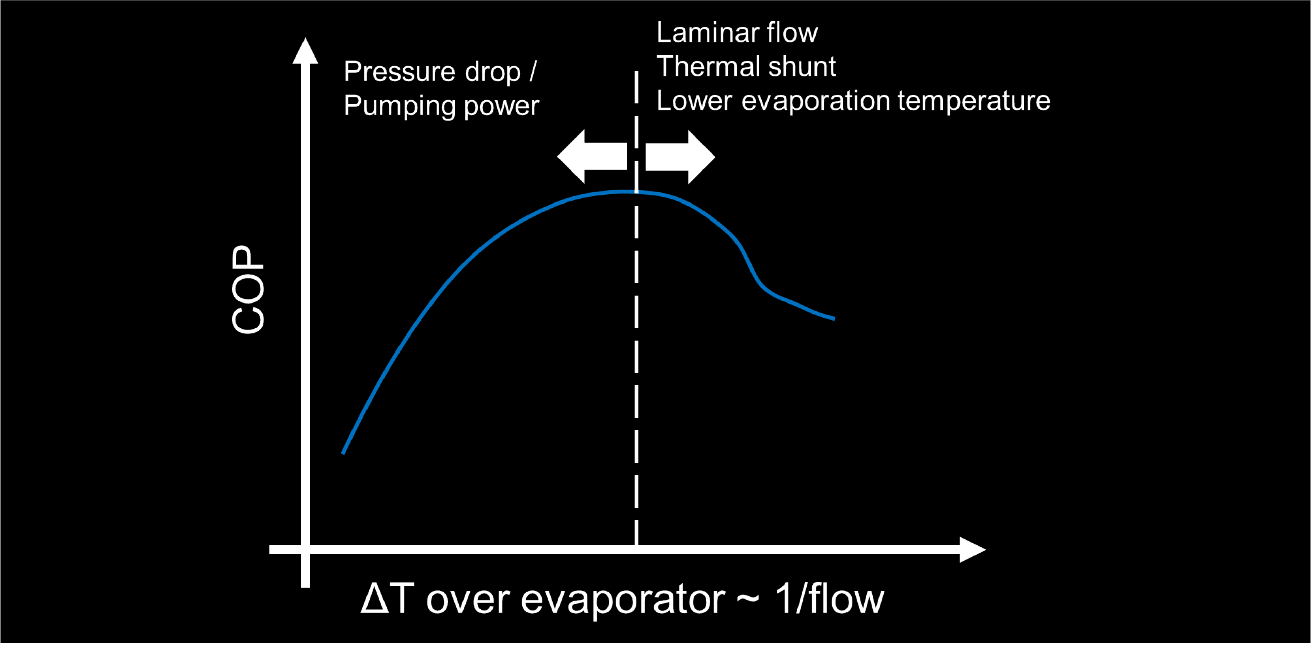

Geothermal heat pumps already have good performance today, but it could be 10 to 40 percent higher if the optimal flow was used in the borehole circuit. For ground-source heat pumps, in particular, it is unknown what the optimal flow is and how it is affected by different conditions, such as depth, number of boreholes and thermal short-circuiting.

Project description

Within the project, we will explore several key questions that currently lack complete answers:

- How does the optimal flow change with different depths and thermal short-circuiting in borehole heat exchangers?

- How does the optimal flow change, for example, with two 500-meter deep boreholes instead of five 200-meter deep boreholes?

- Does the optimal flow shift (and if so, by how much) as the temperature decreases, such as due to the transition between laminar and turbulent flow?

- Does the optimal flow change when coaxial heat exchangers are used instead of U-tubes in the boreholes?

To fill the knowledge gaps, the project proposes the development of a borehole-to-heat pump model from which analytical expressions can be derived for optimal flow. The model will be validated with a test setup on-site at KTH Live-In Lab, and data from real installations. A simple web-based tool will be developed to easily determine installation-adapted optimal flows.

Furthermore, an extensive statistical parametric study will be conducted. The study aims to identify heuristic flows that may not be precisely optimal but are robust across a variety of conditions. This, in turn, will lead to a simpler and faster implementation in real installations.

Project collaboration model