Roller Rig Initiative

KTH Scaled Roller Rig

Project leader: A. Qazizadeh (

alirezaq@kth.se

)

Main project members: R. Giossi, R. Kulkarni, P. Damsongsaeng

Introduction

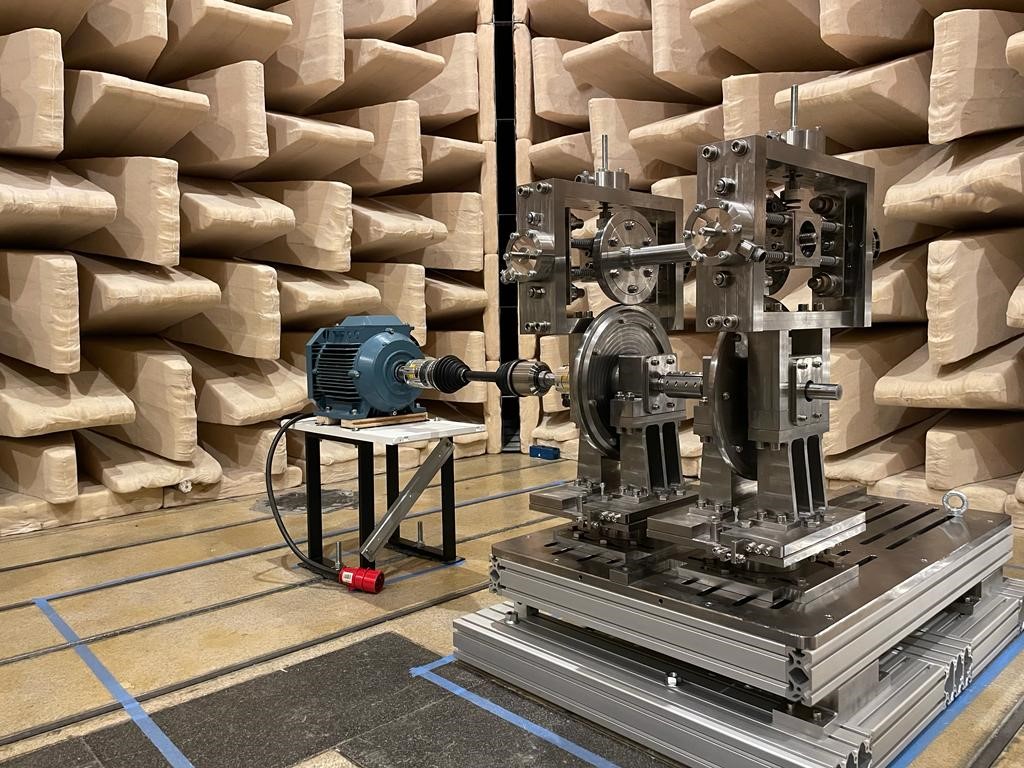

Division of rail vehicles kicked off a project during autumn 2020 for designing and manufacturing an inhouse-built Roller Rig to be used for educational and research purposes.

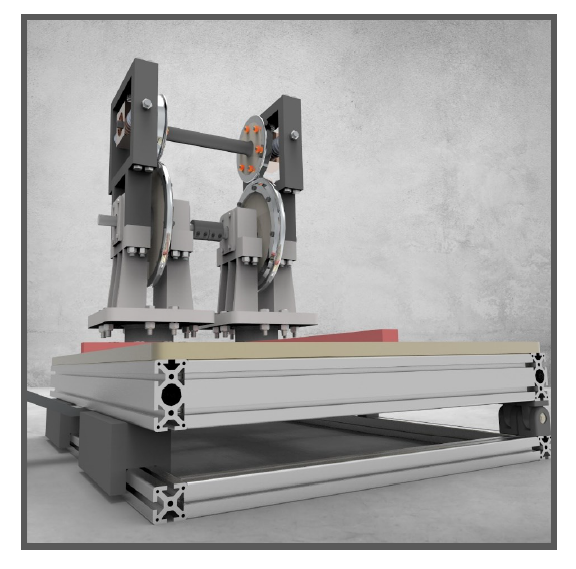

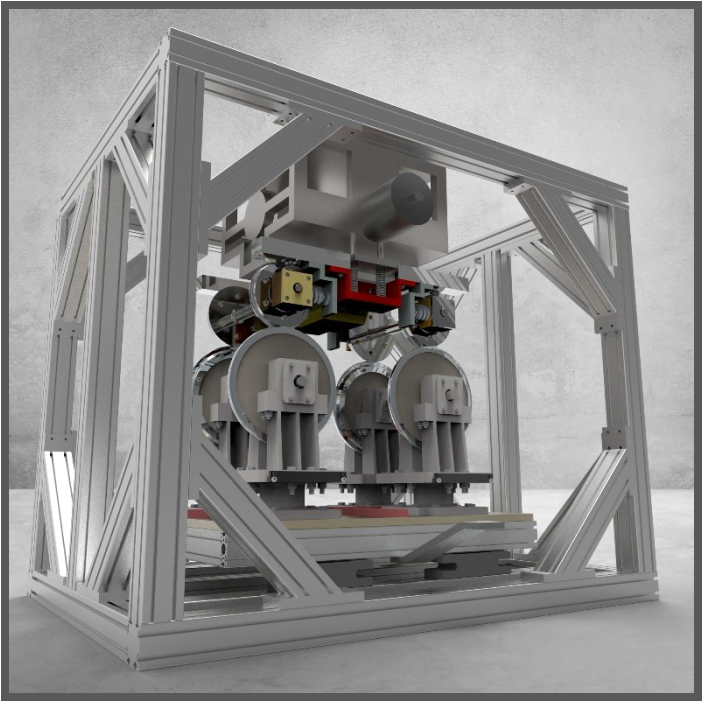

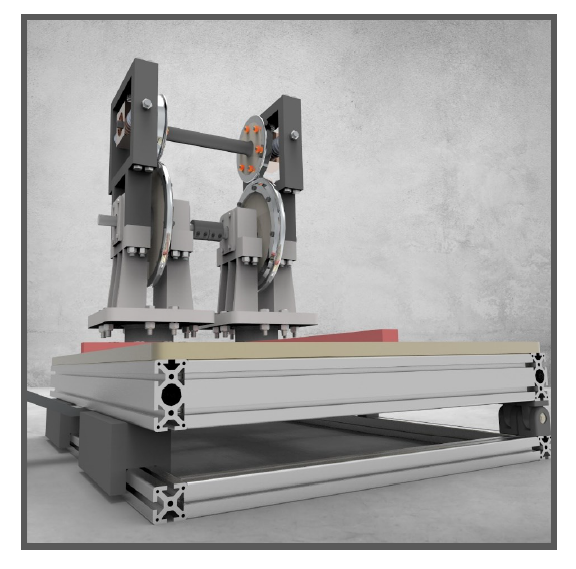

The rig is planned to be built in two phases where in the first phase it models a single wheelset running over a roller-set. Once enough experience from this phase is collected, the project will be continued towards the second phase where a two-wheelset bogie (with possibility of adding carbody mass) will be accommodated over two roller-sets. See the pictures below.

The rig design and concept development were performed with a focus on modularity to allow as much freedom as possible for future research activities. The rig will be capable of running tests at 1/4 or 1/5 scales. The modular design of the test rig will allow for having different wheelbases and gauges for accommodating different bogie types. Wheels and rollers are designed in two parts made of cores and rims. This will allow easy replacement of rims if different wheel or rail profiles are desired. The roller rig is intended to be operated in three main Operation Modes:

- OP1: Simulating tangent track without track irregularity

- OP2: Simulating circular curves without track irregularity

- OP3: Simulating tangent track with track irregularity

The roller rig will be used for different test purposes including:

- OP1:

- Study of vehicle instability (effect of wheel-rail profiles, effect of gauge, effect of suspension parameters and running gears)

- Study of traction and braking (adhesion)

- OP2:

- Study of curve negotiation performance (radial steering index)

- Study of active wheelset steering or active tilting solutions

- OP3:

- Study of ride comfort and different active and passive suspension elements for improving comfort

- All OPs

- Test of unconventional running gears (actuators in suspension system; independently rotating wheels)

- Possibility to test different hardware-in-loop solutions

The first phase of the project is almost finalized by realising a wheelset running over a roller-set modelling the simplest form of wheel-rail contact and dynamics.

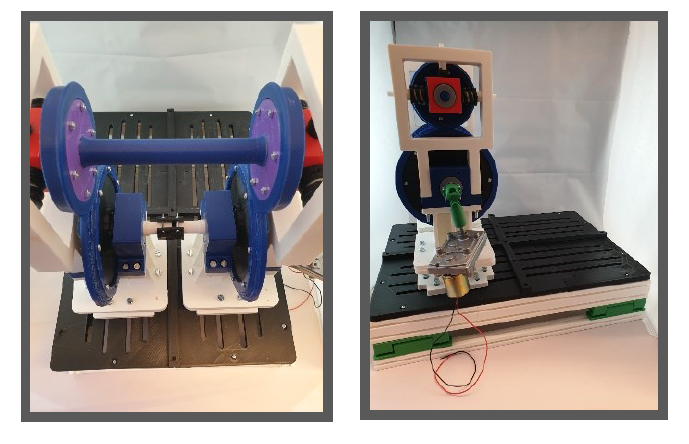

Single Wheelset – Single Roller-set

Around 20 engineers have been involved in the project for realizing this phase including a researcher, doctoral students and several master and internship students. The project has gone through all design steps from modelling, prototyping and all the way to manufacturing, see the pictures below.

The manufactured rig is now mounted at MWL and has demonstrated positive results for operation in OP1. The rig is now in final stages of commissioning where different activities are performed:

- Instalment and adjustment of parts

- Mounting and calibration of sensors

- Setting up the Data Acquisition (DAQ) System, see pictures below

The project life cycle development and management has been according to the best practices from EN 50126 and ISO/IEC 15288 for developing of products with high level of Reliability, Availability, Maintainability and Safety (RAMS).

Collaboration

KTH Division of rail vehicles sees the test rig as a common research platform for collaborative projects together with other rail related research and industrial centres. To this end, interested parties are invited to contact the project responsible, Alireza Qazizadeh ( alirezaq@kth.se ), for submission of research and collaboration proposals.