Corrosion on plastics

Researchers:

Prof. Mikael Hedenqvist (project leader)

Project Description:

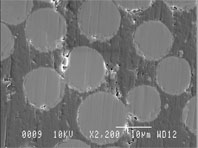

In industry polymeric materials are to a large extent used in process components such as pipes and cisterns, especially in corrosive environments in which metals cannot be used. Often-used plastics are for example GAP, PVC, CPVC and fluoroplastics. A more recent polymeric material is the liquid crystalline polymer (LCP). The choice of the best material requires knowledge on how a given material behaves in a specific environment. Current information on resistance to chemicals or the type of corrosion is often not enough.

The present-day situation within the area of polymer chemistry closely resembles that of the metals area 50 or 60 years ago. Knowledge on corrosion of polymeric materials is only in its beginnings, as are the efforts at standardizing the many different qualities. The goal of the (PhD) project is therefore to investigate and describe corrosion on polymeric materials. An important aspect in this connection is that polymers, as opposed to metals, are not diffusion impermeable. Diffusion, permeability and osmosis in polymeric materials are quite important for the corrosion processes.

Knowledge concerning the interplay between sorption, diffusion and corrosion is to be increased which may make it possible to describe corrosion on plastics using corrosion expressions of a more general nature. This knowledge may also be used to find methods for protecting the materials through suitable additives or other modifications. The materials studied in the project include fibre-reinforced thermosets, fluoropolymers and LCP.

Funding

KK-stiftelsen (The Knowledge Foundation), Industry, Kimab AB