New possibilities in micromachining

New technologies allow heterogeneous high-performance material integration at low cost

The European consortium Q2M, coordinated by KTH, has moved the limits of microfabrication. New fabrication methods have been developed that permit previously excluded combinations of high performance components such as CMOS electronics, thin crystalline layers, piezoelectric materials, memory metals and polymers. Combining conventional microfabrication techniques with new materials, so-called heterogeneous material integration, is notoriously complicated due to the inherent incompatibility of the material fabrication and machining techniques.

“We have enabled different high-performance materials,electronics and plastics to be integrated in the same microsystem at a lower cost,” says Wouter van der Wijngaart, Associate Professor at the KTH Microsystem Technology Lab and Q2M project coordinator.

High-quality materials for excellent MEMS performance

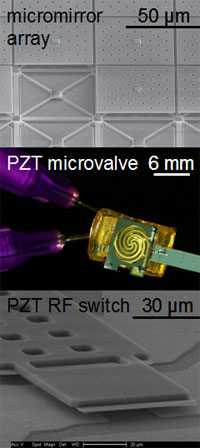

During the past three years, the consortium has successfully tested the new technologies in four microelectromechanical systems (MEMS): micromirror systems for medical diagnostics and therapeutics of the eyes (ophthalmology); low-cost microvalves for a better control of liquids and gases; integrated microswitches for use in wireless communication systems; and atomic force microscopy tips.

The materials are combined at relatively low temperatures using so-called transfer bonding technologies.

“Decimetre-scale areas of high performance material layers are

transferred to microstructured surfaces of semiconductor or polymer

material, using either glue-like adhesive polymers or solder-like

techniques,” explains Wouter van der Wijngaart.

The Q2M research consortium was constructed specifically to cross the limits within heterogeneous material integration. The consortium consists of 12 academic and industrial partners and is sponsored by the European Union.

MEMS stands for MicroElectroMechanical Systems and encompasses

microcomponents, microsystems and microfabrication technologies. MEMS devices have a typical size ranging from 100 nanometre to a few millimeters and are used in a wide range of applications, including the automotive industry, telecom, publishing, medical technology and biotechnology.

More information about Q2M, the consortium partners and their research can be found in this link .

Contact information

Wouter van der Wijngaart, Assoc. Prof. KTH Microsystem Technology Lab and Q2M project manager.