Students make their ideas come true in new Makerspace

A 3D studio, fine mechanical crafting tools and a social meeting point give KTH Flemingsberg’s students new opportunities to take their ideas to the next level.

HP, Google and Apple – all of these enormous companies once started in ordinary garages, where each of their founders had a place to develop new ideas. These spaces for creativity are sources of inspiration as KTH now has inaugurated their own Makerspace.

KTH Flemingsberg’s Makerspace has different kinds of equipment in several rooms. For example, an embedded studio for IT tasks, a crafting studio for fine mechanical work, and a 3D studio with 3D printers and a station for circuit board production. The aim is to create a social meeting point for students, teachers, researchers and industry, where students can take their projects to a new level.

What the students might do in the Makerspace depends on their previous experiences. Students who want to take part in the Makerspace have to start on introduction level, and work their way up. The person with the highest authority in the Makerspace is the manager, Linus Remahl.

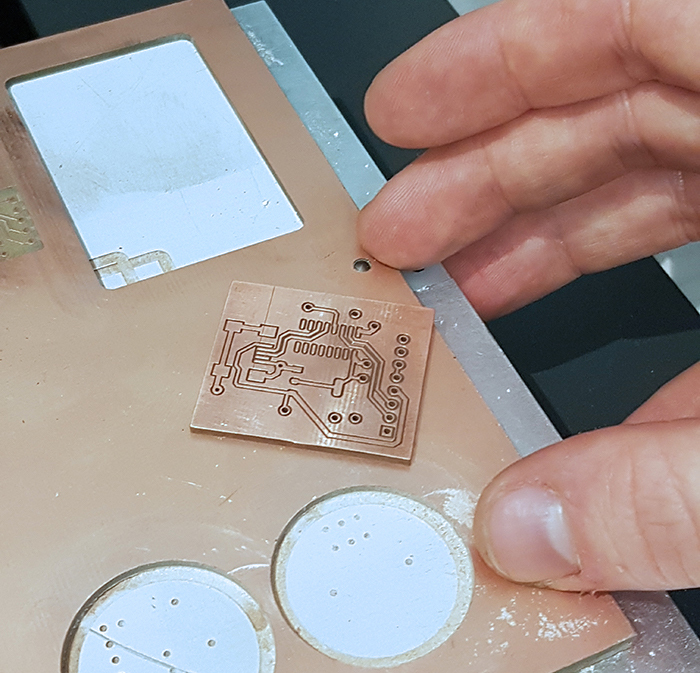

– For instance, I can help the students with creating circuit boards. The machine I work with then is the most expensive we have invested in. We have also got an older machine from the 90's, but the new one is almost fully automatic and doesn’t damage the drill heads as often happens during the circuit board production.

The Makerspace pre-started before the opening ceremony

About a hundred invited guests participated in the opening ceremony. It started with a few words from Sebastiaan Meijer, deputy head of the CBH school, followed by a short background presentation by the project coordinator Anders Cajander. Mikael Lindström, head of the CBH school, then declared the Makerspace inaugurated. Several students presented their projects on site, which made it obvious that the Makerspace had already been in use for some time.

– We wouldn’t be able to do these 3D printed objects without the Makerspace. It is a great resource to have Linus here, who can provide us components. We bought the majority of the components ourselves, but the help with missing parts has saved us a lot of money, says Jonathan Kardelind.

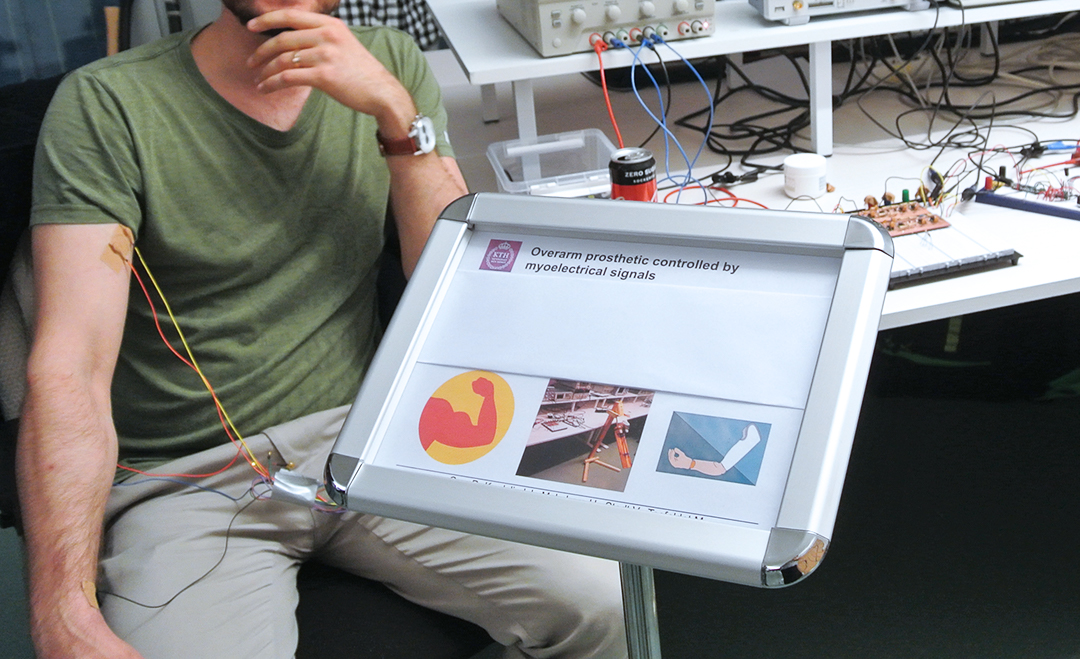

Together with fellow students Henrik Malmberg, Viktor Stedt and Paolo Cruz, he has created a myoelectrical prosthetic arm. The prosthesis is crafted in wood and merged with 3D printed plastic components. The prosthesis is linked to Viktor Stedt’s arm by electrodes. When he stretches his biceps, the prosthetic arm follows.

– The time spent from idea to a functioning prosthesis wasn’t long. We worked with the design for about a month. We have been in the Makerspace the last month, doing soldering and printing. It is truly inspiring to construct something in the computer and then print it in 3D, says Jonathan Kardelind.

Important designated workspace

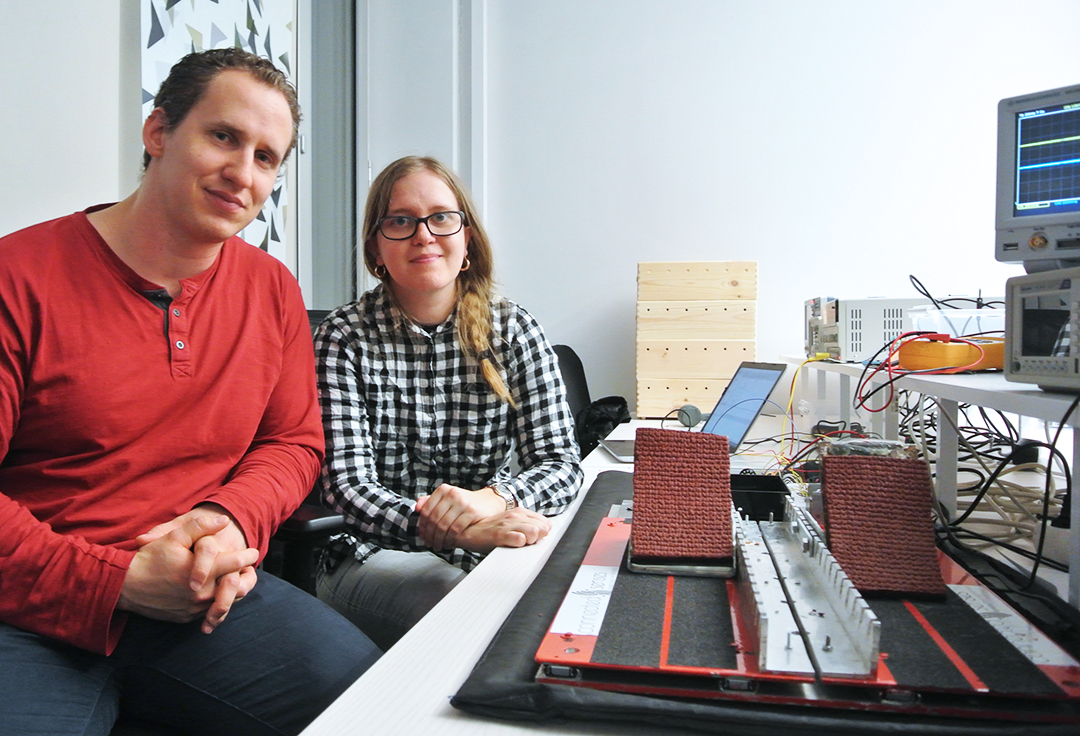

At another table we find medical engineering students Sanna Enmark and Daniel Karlsson, with a starting-block used in track and field. The students are doing their degree project for The Swedish School of Sport and Health Sciences. Their crucial problem right now is to find a way for the starting-block to communicate with a mobile app.

Makerspace has been a great service for Sanna Enmark’s and Daniel Karlsson’s project group.

– We got help with producing circuit boards, for instance. But most important, we have a designated place to work in. It would have been hard to match our project work with finding free working hours in the ordinary labs. And a top of that carrying around the starting-block and finding storage for it, says Daniel Karlsson.

Access to the Makerspace will be presented for students during their project courses at KTH Flemingsberg. Daniel Karlsson’s opinion is that the Makerspace should be introduced as early as possible.

– Makerspace is a new thing, but it would have been good if we had this kind of possibility already in our second year of studies. I sure hope KTH will see an increase in these kind of creative places, says Daniel Karlsson.