Safer green hydrogen production to reduce emissions in industry

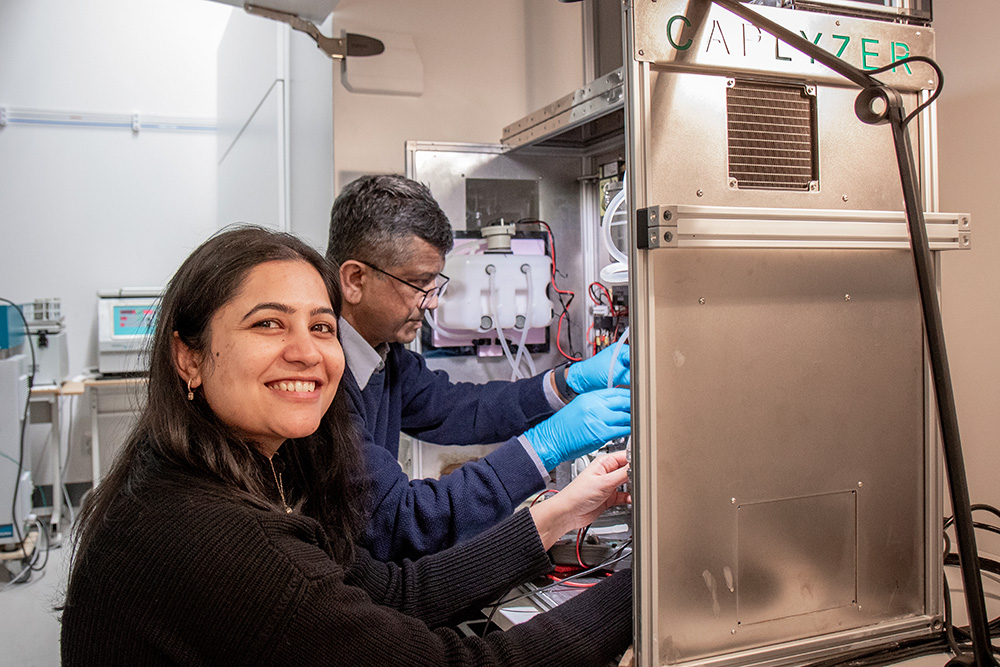

In KTH Professor Joydeep Dutta's lab, researchers have developed technology that can make the production of green hydrogen safer, cheaper, and scalable. With spinoff company Caplyzer, they are now aiming to bring the technology to the market. Joydeep Dutta and CEO Rutvika Acharya share their vision and the journey from research to company.

Hydrogen might not be the first thing that comes to mind when it comes to mitigating climate change, but it's a hidden backbone of modern industry—used everywhere from making steel for buildings and cars to producing fertilizers that help grow your food.

Right now, almost all of that hydrogen comes from fossil fuels, pumping out enormous amounts of CO₂. Green hydrogen offers a climate-friendly alternative by splitting water into hydrogen and oxygen using renewable energy, but traditional methods come with risks—current electrolyzer technologies produce both gases at the same time and mixing these gases can cause explosions unless expensive membranes are used to keep them apart.

"We have figured out a way of decoupling the production, so we never produce hydrogen and oxygen at the same time" says Rutvika Acharya. “This way, the gases can never mix, so the process becomes safer. It’s also cheaper, because we can remove the expensive membranes and we are more sustainable as, unlike traditional electrolyzer, we do not use any rare earth metals in our design. Combined, these features add up to a cost advantage of about 30 % compared to other solutions.”

Aiming to decarbonize industry

Green hydrogen is produced through the process of electrolysis, using electricity generated from energy sources such as wind, solar, or hydropower. Today, many industrial processes use fossil-based hydrogen in their production.

"CO2 emissions from the steel, petrochemical, and ammonia, industries amount to almost a billion tons annually", says Joydeep Dutta. That is equal to the entire aviation industry. "With our technology, we want to help these kinds of established industries to decarbonize".

Development a team effort

While the idea and problem formulation has been on Dutta’s mind for at least 10 years, the development of this, now patented technology was a team effort. A group of interns from Spain started tackling the problem, and their solution caught the attention of then PhD student Esteban Toledo.

"When our way of producing hydrogen started working, I could barely believe it myself", says Dutta. Water splitting is not new, it has been done since the 18th century. Why has nobody thought of such a simple thing as to decouple hydrogen production from oxygen production that have different energy requirements for the reaction to happen?"

Scaling not a problem

With funding from Vinnova’s VFT program, administered by KTH Holding, the team brought in researchers from RISE to conduct an independent review who confirmed that their findings were correct. The next step was to build up the capacity and protect the IP.

"Today, we have a 1 kilowatt system that works", says Dutta. "That means we are producing up to 200 liters of hydrogen every hour, which is proof of principle that scaling is not a problem."

Acharya continues:

"Our focus right now is commercial validation with pilot customers and scaling the production capacity of the electrolyzer. Once we do that, we can put all of our effort into getting ourselves commercially ready for sales, which would mean building a 100 kilowatt or even megawatt system."

Support from KTH Innovation

They first contacted KTH Innovation in 2021. Since then, the team has gotten support with funding, business coaching, and participated in programs. In 2023, they received an investment from KTH Holding.

"I have to mention Siimon Vaske (business development coach at KTH Innovation and portfolio manager at KTH Holding) who always had my back and asked me the critical questions needed to keep going", says Dutta. "Without KTH Innovation, I don’t think we would have been even a fraction of what we are today."

One of top 15 startups in Europe

In the fall of 2024, Rutvika Acharya joined the team as CEO. Since then, Caplyzer has been recognized as one of the top 15 startups in the EU that will pitch at the EU-Startups Summit 2025, selected from over 1,500 applications.

"We are currently looking for investors to support our seed round", says Acharya. "We are also looking to validate our technology with more customers. If you’re interested, reach out!"

By: Lisa Bäckman

About Caplyzer

- KTH professor Joydeep Dutta has founded a number of startups in his career. Two more examples are Kitocoat , that has developed an edible coating to prolong the shelf-life of fruits and vegetables, and Stockholm Water Technology , focusing on cleaning water using electricity, without the need for membranes or chemicals.

- Rutvika Acharya studied Vehicle and Aerospace Engineering at KTH. After graduation, she spent seven years working for a construction company in various leadership roles in product development, product marketing and strategy in Lichtenstein, the United States and Singapore. Two years ago, she quit her job to venture into the world of startups. She is also the founder of MOAI, aiming to transform global talent mobility with help of AI

- KTH Holding has invested in Caplyzer. KTH Holding is a state-owned company investing in very early stage companies from KTH. They invest and help researchers and students to build companies from their ideas, research results and intellectual property rights (e.g patents).

- www.caplyzer.com

- Contact: rutvika@caplyzer.com