Process of recycling batteries about to become much easier

Researchers at KTH managed to improve the process of recycling batteries with the help of ordinary cellulose fibres. This can separate battery metals from other materials.

The use of batteries is expected to increase significantly in the coming years due to the electrification of our society. At the same time, it is a major challenge to supply the increased battery production with the necessary metals. Furthermore, politicians at EU level have voted through requirements for spent batteries to be largely recycled.

With this in mind, KTH doctoral student Billy Hoogendoorn and his colleagues have worked on ways to simplify the recycling process of batteries. The process, as well as the infrastructure that enables large-scale recycling, are still in their infancy. Hoogendoorn and his colleagues argue that new, efficient and industrially applicable solutions must be developed in the near future.

Toxic cadmium metal

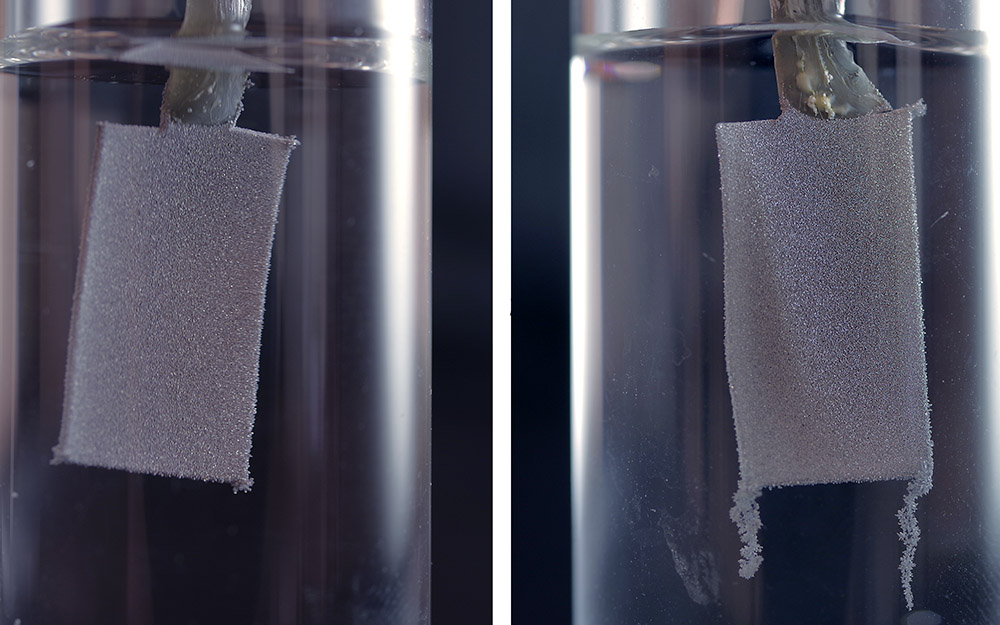

The research includes placing cellulose fibres in the form of nanocellulose in a bath of dissolved battery metals. To the surprise and delight of the researchers, structures in the form of dendritic trees of cadmium grow on the electrode in the bath. The result is a separation of the metals nickel and the toxic cadmium metal from the rest of the material mixture.

"The study shows that very small additions of half a gram of cellulose fibres per litre of liquid lead to the formation of large tree-shaped dendrites, visible to the naked eye. The increase in dendrite formation means that the amount of material recovered from the aqueous solutions can increase significantly, up to 30 per cent," says Billy Hoogendoorn, a researcher at the Wallenberg Wood Science Center at KTH.

More than 99 percent cadmium

He adds that a detailed analysis also shows that when this type of so-called electrodeposition is carried out in solutions containing nickel and cadmium, the deposited material consists almost exclusively of cadmium, amounting to more than 99 per cent.

"This work represents an exciting first step in how nanocellulose can be used to influence the efficiency and selectivity of metal recycling processes and selectivity of metal recycling processes. We believe that many more aspects can be evaluated", says Hoogendoorn.

The research has resulted in a scientific article accepted in the journal Nanoscale Advances and put on the cover of the prestigious journal of the Royal Society of Chemistry.

The research has, among other things, been carried out on backup batteries at Swedish hospitals. It has been funded by the Wallenberg Wood Science Center 2019-2023 and was supervised by Richard Olsson, Associate Professor at KTH.

Text: Peter Ardell

For more information, contact Billy Hoogendoorn at billyho@kth.se.