Stronger-than-steel fibre spun from wood

Whether they need to be strong as steel, or as soft as cotton, products of the future could be sourced from the forest, using new techniques developed at KTH Royal Institute of Technology.

Researchers at KTH have developed a way to make biodegradable cellulose fibres that are stronger than steel or aluminium when weight is taken into account.

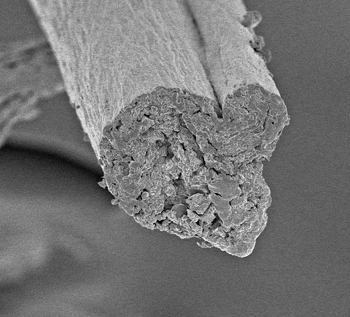

The technique draws on the cellulose fibres that make up a tree. Each single fibre is composed of as many as 40 million smaller fibres, or “fibrils”. While these fibrils have been separated from each other before, the KTH researchers and their collaborators in Germany succeeded in doing what no one else has. Fredrik Lundell, one of the researchers, says the team bound these fibrils together into filaments as strong as the original fibre in the tree. The filaments offer a wide range of uses, from manufacturing to clothing.

“We have taken out fibrils from natural cellulose fibres,” Lundell says. “Then we have assembled fibrils again into very strong filament. It is about 10 to 20 microns thick, much like a strand of hair.”

The research offers potential for creating natural clothing textiles based on wood instead of cotton, or even replacing fiberglass in cars, trucks and boats.

Lundell says that that unlike existing processes for making strands of cellulose, such as rayon, their composition process is environmentally friendly and sustainable. The only other ingredient in the process is sodium chloride – commonly known as table salt – for binding the fibrils together.

“We can control how the fibrils are arranged in the thread,” Lundell says. “If they are aligned with the grain line, the material is stiff and strong. Are they not so aligned, this leads to a material that is more elastic.”

Lundell says these variations mimic those that occur in nature. A tree is alternately rigid and flexible, in order to withstand the force of wind and its own weight. As trees grow, the fibril angles change in different parts of the trunk so the tree can handle any stress.

The new technology promises not only biodegradable structural materials but soft natural textiles that could be substituted for cotton, which is widely believed to be close to reaching peak cultivation.

“Cotton cultivation requires large amounts of water,” Lundell says. “Take for example the Aral Sea, which more or less disappeared as a result of the cultivation of cotton in Asia. If we are to have a 100 percent sustainable society then we need more materials that have a natural place in the natural cycle.”

Lundell adds that the work continues with aim of lining up fibrils so that alternatives to fiberglass can be produced.

“Our research may lead to a new construction material that can be used anywhere where you have components based on glass fibers, and there are quite a few places,” he says. “The challenge we face now is to scale up the production process. We must be able to make long strands, many threads in parallel – and all this much faster than today. Nevertheless, we have demonstrated that we know how this should be done, so we've come a long way.”

He says that by manipulating the nanostructure and adding other components such as carbon nano tubes in the thread, other applications become possible, such as clothing with embedded electronics.

Söderberg says that by working with fibrils as the basic component, the technology retains the natural structure of cellulose. “That means that the material is 100 percent compatible with nature,” he says. “Cows eat cellulose. Likewise, dead trees and plants are broken down by natural processes.”

The work was mainly carried out at the Wallenberg Wood Science Center at KTH, but in cooperation with Deutsches Elektronen-Synchrotron elektronsynkrotronen (DESY) in Hamburg, Germany.

Söderberg says that much of the current research progress comes as a result of interdisciplinary collaboration. In this case, the team within the Wallenberg Wood Science Center consisted of researchers in fluid physics and researchers in fibre and polymer technology, with Professor Lars Wågberg as the point person. Also involved is Stephan Roth at DESY in Hamburg. The availability of advanced measurement techniques in DESY’s synchrotron light facility, and the Hamburg scientists’ expertise has been crucial, Söderberg says.

Peter Larsson