Aerosol nozzles

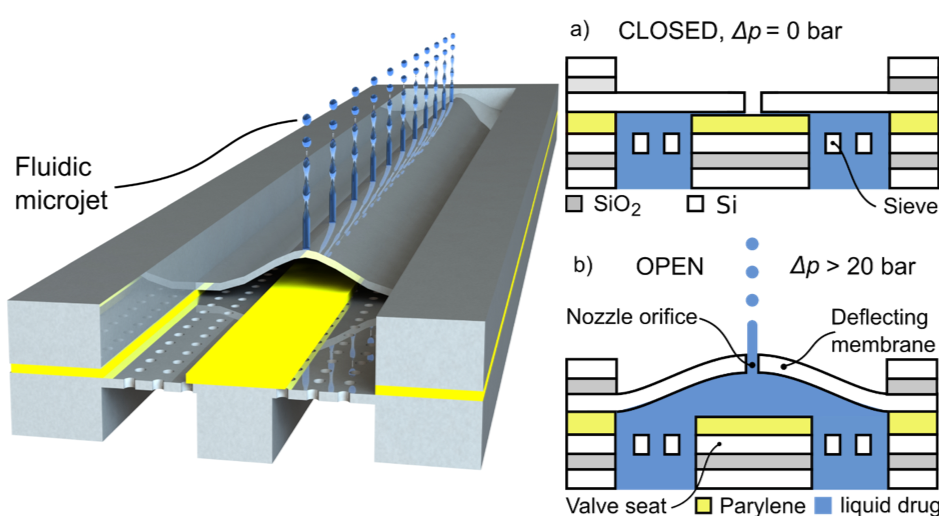

We manufacture arrays of hundreds of small orifices in a size range of micrometers in free standing silicon membranes, which are a mere 2 µm thin. Even though they are basically see-through our membranes can stand pressures upwards of 25 bars. We then use Parylene, a biocompatible Polymer, as a bonding material to form spray chips that include two of the aforementioned membranes: one membrane that acts as a sieve, and one membrane that implements spray nozzles used to aerosolize a liquid at high pressure. We use these chips to generate Aerosols for lung disease treatment.

Improving drug delivery to the lung: liquid inhalers

Lung diseases are a major cause of illness worldwide. According to recent estimates 3% of the world population suffers from Asthma. More severe chronic lung disease in the form of chronic obstructive pulmonary disease (COPD) is expected to be the fourth leading cause of death worldwide by 2040 according to the WHO.

At MST we are actively working on improving the state of the art in portable medical inhalers, which are used to treat chronic lung disease. Recent advances in liquid inhalers have brought new aerosolization techniques such as Rayleigh-jet based inhalers, which are capable of producing highly monodisperse liquid aerosols. Such Aerosols can be used to target specific regions of the lung, reducing side effects of the medication.

Rayleigh-jets are easily generated by forcing a liquid drug through orifices in a thin membrane at high pressure. However, portable medical inhaler systems are prone to bacterial contamination and the orifices in the spray chips present open passages towards the drug supply. That is why we have been working on a valved aerosol spray chip, a system that sprays a microjet when actuated and seals against bacterial ingrowth into the spray nozzle in the closed state. The sealing mechanism is realized by placing a valve seat directly underneath the spray orifices.

Our system aims to enable the safe reuse of spray chips for multiple spray operations over an extended period, lowering the cost of treatment while increasing patient compliance.

Proceedings IEEE MEMS 2019, Torben Sebastian Last, Göran Stemme and Niclas Roxhed “The first demonstration of an Aerosol nozzle valve”.

Key words: BioMEMS, drug delivery, fluidic microjet, inertial microfluidics, respiratory tract disease treatment