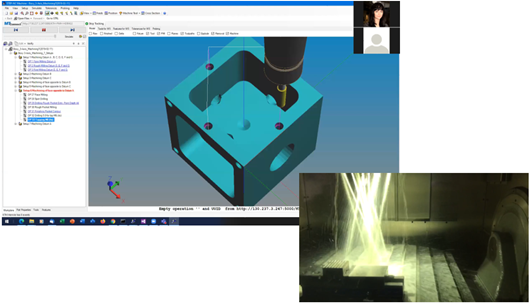

PMH Webinar: Digital twinning in machining – Application examples in PMH Application Lab testbed

Publicerad 2021-01-05

The seminar “Digital twinning in machining – Application examples in PMH Application Lab testbed” was hosted 2020-10-23, by PMH Application Lab and had 13 participants from research and industry.

The seminar acted as a dissemination event of the Swedish-German testbed project where the following applications developed on the Swedish side of the project were presented.

- Smart sensing framework is a process of acquiring sensor data during the machining process and further analyzing the data to make assertions about surface quality. A framework for sensing online production data has been developed and tested and a demonstrator interface for visualizing the data has been designed

- Tool life use-case: The information management through the working steps from design of a cutting tool assembly to analysis of achieved machining process result contains many gaps. There is no digital thread to support a circular workflow from the developed process plan including tooling solution to the quality of a machined part. Data collected from a machining process has very limited or no relation to the context of the product and the tool. A setup for model-based tooling optimization enabled by the digital thread and based on international standards was demonstrated.

A huge thank you to all the participants, including representatives from Scania, Leax, Fraunhofer IPT, Chalmers University, KTH University, and PMH Application Lab, for the interesting discussions that could lead to future collaborations and continuation of this project.