ReMedBuild - Circular Connections: Bridging Healthcare and the Built Environment

Cities struggle with unchecked medical waste, as hospitals rely on single-use plastics without recyclability regulations. This overwhelms landfills, worsens air pollution from incineration, and increases public health risks from hazardous waste mismanagement.

With 90% of medical waste in transitional economies dumped or burned improperly, cities bear the economic burden of rising disposal costs and environmental damage. Without sustainable and innovative solutions, healthcare waste will continue to strain urban waste management systems.

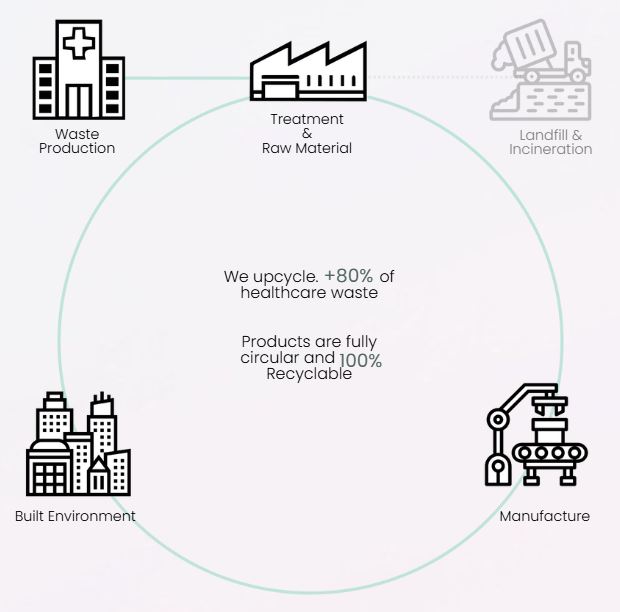

We imagine circular cities where we transform local waste into local products on a global scale through a replicable circular system that upcycles 70% of healthcare waste. Our suggested method focuses on closed-loop recycling & upcycling for hard-to-recycle waste. It can process textiles and plastics, and adapts to different waste management systems, making it replicable and scalable internationally. This allows us to license a turnkey model, scalable from B2B to B2G. With a single production line, we craft beautifully designed, high performance circular products, where our product par excellence is Sustain TH40S thermal insulation.

Background

The solution meets a critical need in Europe's transition toward circular construction, urban climate adaptation, and waste reduction. The project targets multiple high-impact user groups: public and private developers; architects looking for sustainable, innovative materials for renovation; healthcare institutions seeking circular solutions to reduce waste management costs; and policy-makers and cities striving to align with EU carbon neutrality and green public procurement goals.

The thermal insulation market is currently dominated by materials such as mineral wool, expanded/extruded polystyrene and bio-based alternatives (e.g. hemp, flax, sheep wool). While innovations in circular insulation are emerging (e.g. recycled textiles, cellulose from paper), there are no direct competitors in the market focusing on the repurposing of healthcare waste (HCW). SUSTEIN is pioneering the way by offering a comprehensive collection service aimed at recycling at least 70% of HW Group II and Ill. This presents a significant market opportunity, addressing a critical need for sustainable waste management solutions. Our undisputed main market is thermal insulation materials, where competitors are not the companies, but the materials their products are made of.

SUSTEIN's product is the only polymer-based material with semi-rigid properties, making it ideal for use in installations, ceilings, basements, and other spaces prone to high condensation, temperature fluctuations, or exposure to marine or humid environments. Despite being positioned as a premium product due to its extensive features, SUSTEIN maintains competitiveness through strategic pricing and scalability, enabled by targeted investments in production infrastructure.

SUSTEIN's materials complete the voids that competitors have not solved, creating a unique and improved product. This project introduces a disruptive, circular solution that goes beyond incremental improvements.

Aim and Objectives

The project aims to:

- Certify a circular thermal insulation product derived from HCW for scalable use in buildings

- Validate the product in real-world conditions through pilot installations

- Prepare for industrial-scale production and establish a sustainable supply chain

- Launch the product in EU construction markets with a strong business model and market entry strategy Contribute to EIT C&C financial sustainability through equity participation

- Raise awareness, promote adoption, and contribute to circular construction policy development at EU level

Project Partners

Listed one per row

-

Sustain Material S.L

-

KTH, Department of Energy Technology, Division of Heat and Power Technology

Funding is provided by European Union, EIT Culture & Creativity.

TimeFrame: 2025 - 2026

Researchers

For more information about this project, please contact Farzin Golzar