Efficient heat exchanger ready for testing

A 3D-printed heat exchanger in aluminum filled with phase change material – that is what Professor Viktoria Martin and colleagues from KTH have experimented within a laboratory environment. The result is a prototype with both high energy density and high power. The next step is to install and test it in a real ventilation system.

"The need for storage is enormous. We will require a mix of storage techniques and use different solutions depending on specific cases. And there is a lot to gain on the user side in terms of shifting the demand for heating and cooling in time when integrating fluctuating renewable energy sources," says Viktoria Martin .

Materials that undergo phase changes, such as ice melting into water, can store significant amounts of energy in a small volume. This possibility is what Viktoria Martin, Professor of Energy Technology at KTH, has sought to take advantage of in a thermal project to create a combined heat storage and heat exchanger that uses air as the heat carrier.

"With phase change materials, the goal is to maximize the amount of thermal energy that can be stored in a limited volume. This development path will be crucial for electrification and for making the entire energy system as climate-smart as possible," says Viktoria Martin.

Previous attempts to change phases and use air as the heat carrier have not worked well because air does not have good heat properties, according to Viktoria Martin. However, the advantage of using air is that it eliminates the need for a liquid heat carrier.

"It's about avoiding an additional heat exchange," says Viktoria Martin.

One challenge with phase change materials is that while they can store a lot of heat, they are insulating towards the core and have poor heat conductivity.

"So the rate of heat transfer, the power, is often quite poor. Therefore, we have worked with mini-channels to ensure that the air has a large contact area as it flows through the phase change material," says Viktoria Martin.

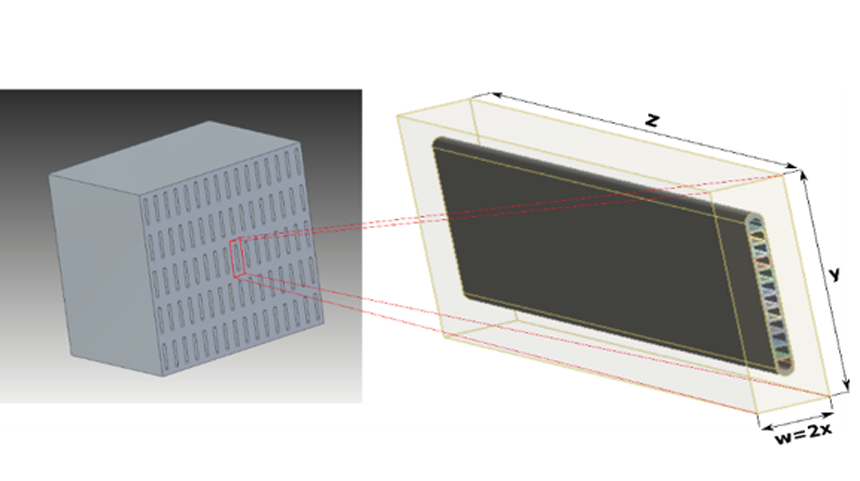

In the project, they used aluminum and 3D-printed various prototypes of heat exchange batteries, filling them with a phase change material that melts and solidifies at around 20 degrees Celsius. The battery is 80% filled with the phase change material, while the rest consists of the mini-channels, providing a large surface area for heat exchange.

The idea is for the final product to be placed in, for example, ventilation ducts, to be charged with cooling during the night and used for cooling during the day. Other applications include use in vehicles. For an electric car, it can increase the range if the electric battery does not need to be used as much to provide comfort cooling inside the car.

"We have achieved a high energy density, approximately 40 kWh per cubic meter, which is about three times more than in chilled water storage. The power performance is also good, reaching 17-26 kW per cubic meter," says Viktoria Martin.

The next step is to seek funding to be able to conduct a trial installation in a real ventilation system for practical testing.

What are the biggest challenges for the development of storage and its significant contribution to the energy system?

"First and foremost, it's about being able to see that energy services exist within a system and not looking at production, transmission, and use separately, but rather striving for sector coupling and its benefits. Storage plays a significant role in that. Additionally, the policy aspect is crucial. For example, storage services should not be subject to double taxation, both when purchasing electricity to charge a battery and when delivering the energy service. It would disrupt profitability," explains Viktoria Martin.

What do you think about the future of storage with phase change materials?

" Sweden has invested for a long time in phase change materials but the technology has not come to commercial implementation at large scale. It's time for test beds so we can show what the technology is capable of."

Text: Daniel Hirsch, Energiforsk and TERMOinnovation

Read more about the research in Journal of Energy Storage (publication)