Method recycles batteries faster, with less environmental impact

As the electrification of society increases, so does the amount of used batteries that need to be recycled. Scientists at KTH have developed a new method to recycle valuable metals from used lithium batteries.

Is it possible to extract metals from a lithium battery in half the time it normally takes? Is it possible to use acids that are common in most homes worldwide for the extraction process? The answer is yes. Scientists at KTH have discovered a way.

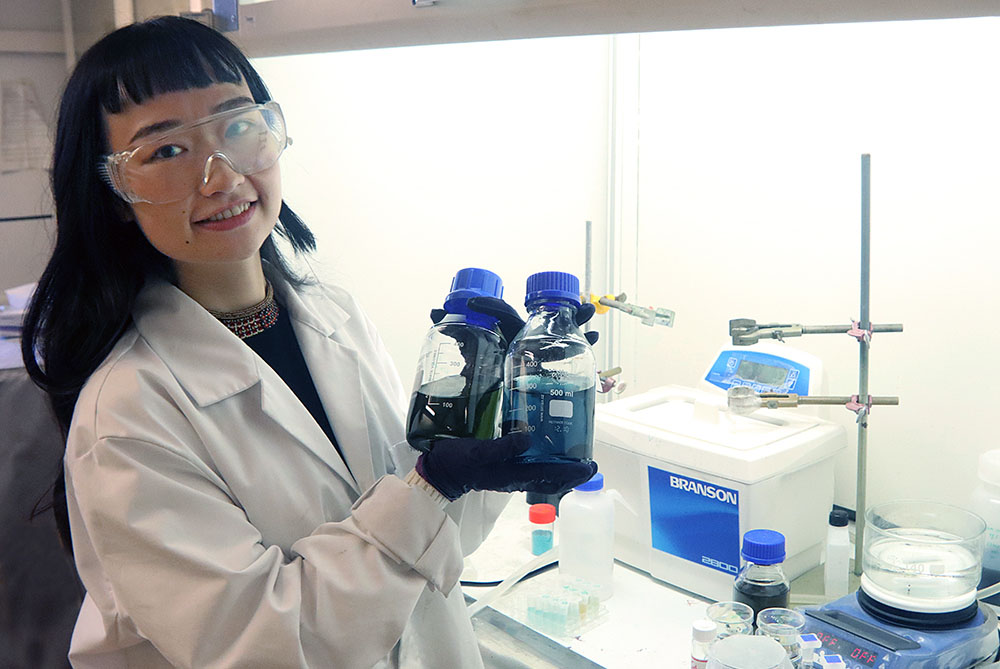

In a scientific article published by the journal Green Chemistry scientist Xiong Xiao, a postdoc at the Division of Polymeric Materials at KTH, explains how it works using ultrasound.

“We perform the metal extraction in half the time it normally takes and we take out more metal ion than normally reported in scientific literature. In the extraction process we use mild acids such as acetic acid and citric acid instead of sulfuric acid, which is very beneficial from a work environment and sustainable development point of view,” says Xiong Xiao.

Ninety-nine percent recycled

The scientists have worked with the most common lithium-ion batteries in the world—the kind found in Tesla cars and iPhones. They go by the name NMC-batteries and besides lithium they contain nickel, cobalt and manganese. The scientists have been able to extract up to as much as 99 percent of the metal in the batteries.

“With ultrasound Xiong Xiao has discovered a way to eliminate the need for chemicals normally used, such as strong acids that are nearly unmanageable,” says Richard Olsson, scientist colleague and university lecturer at The Division of Polymeric materials at KTH.

“She has conducted extensive research to understand at what temperatures and concentrations of the more mild acids the ultrasound can help with the extraction in the best way.”

The significance of ultrasound

Olsson adds that the extraction is “residue layer migration controlled”, which means that it is in the interface of the grains in the crushed batteries where the bottleneck is located for the extraction. The implication is that this is where the ultrasound is of great significance.

“Going forward, now that we have reported this new method, scientists can focus on optimizing the ultrasound even further for this particular interface. For instance using different levels of intensity and frequency in order to reach even faster extraction of the important and expensive metals we want to recycle.”

Xiong Xiao’s work is a part of PERLI (Process for Efficient Recycling of Lithium Ion Batteries) project 48228-1 financed by The Swedish Energy Agency. Another financier is the battery company Northvolt.

For more information, contact Xiong Xiao at xiongxi@kth.se or 070 - 077 56 59

Text: Peter Ardell