Off-Stoichiometry Thiol-Enes (OSTE) - The first polymer system developed for labs-on-chip

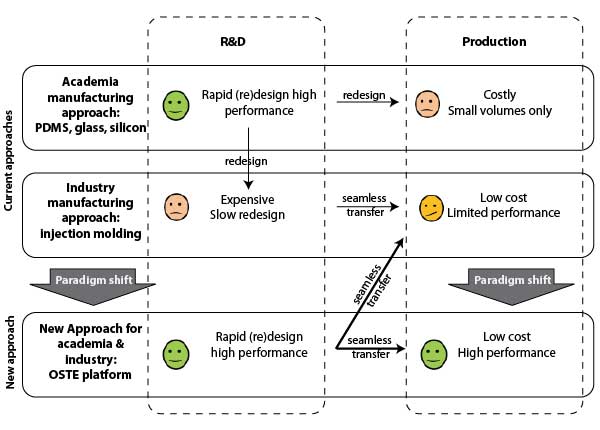

The problem: The field of lab-on-chip (LoC) has demonstrated the integration of several chemical functions onto a single chip device, and has evolved as a research field on its own during the past decade, as is illustrated by the more than 10 000 papers published in the field. Nevertheless, the number of commercial LoC products remains very low. To a large extent, this research-to-application gap can be ascribed to the lack of a consistent material and fabrication technology for both academia and production.

Most of the conceptual microfluidic device development is still done using poly(dimethylsiloxane) (PDMS), which remains the material of choice for proof of concept prototyping since its introduction in the 1990s mainly because of its ease of use and attractive mechanical elastomeric properties. Unfortunately, for most applications a prototype conceptual device based on PDMS needs complete redevelopment to realize a commercial proto- type. The reason is twofold, firstly, because the elastomeric properties are inadequate for many commercial products that need invariable surface chemistry and mechanical strength. Secondly, the PDMS fabrication processes are difficult to scale up and contain assembly steps, such as slow thermal curing or manual handling of thin elastomeric films that are incompatible with medium or large-scale manufacturing.

Objectives

The overall objective of our research is to bridge the “lab-to-fab-gap” and move from today’s use of suboptimal off-the-shelf materials to a novel polymer platform, adapted for rapid prototyping of labs-on-chip but at the same time having material and processing properties compatible with large scale production.

Results

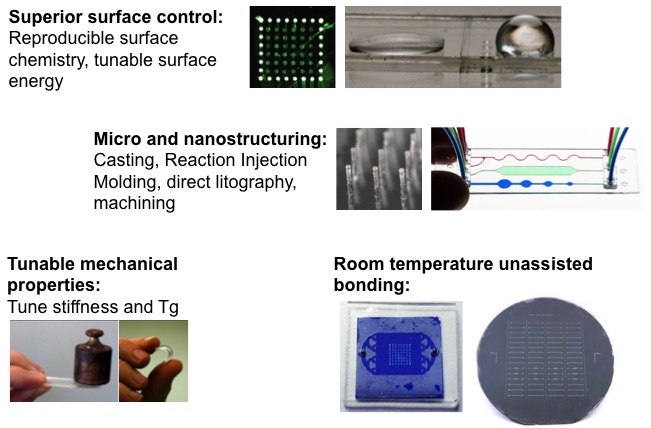

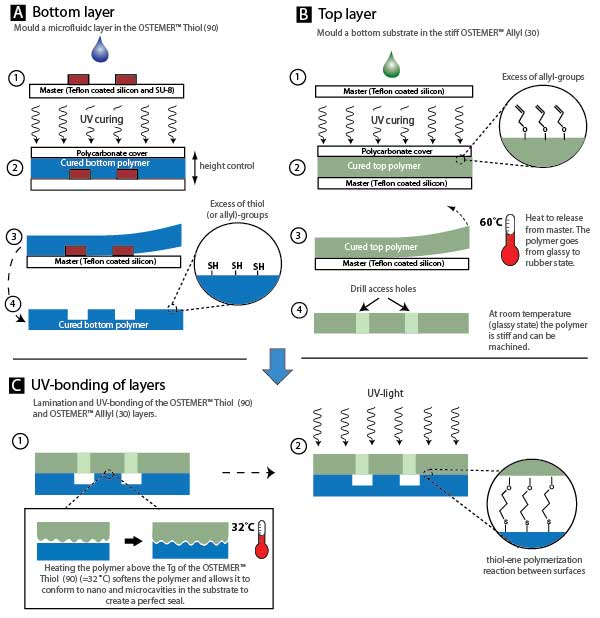

We have developed the first rapid prototyping polymer system specifically addressing many of the shortcomings of PDMS, such as poor mechanical properties, absorption of small molecules and difficulties to permanently modify the surface. The new polymer platform is based on off-stoichiometry thiol-ene (OSTE) chemistry (Carlborg, Lab Chip, 2011). This polymer system is a rapidly UV-curing system allowing for tunable mechanical properties (rubbery-like to thermoplastic-like), tunable surface chemistry (built in molecular surface anchors that can be used for direct and permanent surface modification) and a low-temperature direct bonding process not requiring any surface activation or glues. Moreover the manufacturing process is compatible with standard soft lithography micropatterning.

The technology has been successfully demonstrated for packaging of biofunctionalised QCM sensors (Sandström, Transducers, 2011), bonding to spotted protein and DNA-microarrays (Carlborg, microTAS, 2011) and wafer-level integration and bonding (Carlborg, microTAS, 2011, Saharil, Lab Chip, 2012).

Current research also focuses on direct micropatterning by lithography and off-stoichiometry thiol-ene-epoxy OSTE(+), which has further advantages such as bonding to almost “everything” as well as no leaching of uncured components (Saharil, MEMS, 2012).

The polymer system has been commercialized and further developed by Mercene Labs . More information can be found on their homepage.

Journal publications

- Beyond PDMS: off-stoichiometry thiol–ene (OSTE) based soft lithography for rapid prototyping of microfluidic devices

- Biocompatible "click" wafer bonding for microfluidic devices

- UV initiated thiol-ene chemistry : a facile and modular synthetic methodology for the construction of functional 3D networks with tunable properties

- Integration of microfluidics with grating coupled silicon photonic sensors by one-step combined photopatterning and molding of OSTE

- Dry adhesive bonding of nanoporous inorganic membranes to microfluidic devices using the OSTE(+) dual-cure polymer

- A Comparative study of the bonding energy in adhesive wafer bonding

- Rapid mold-free manufacturing of microfluidic devices with robust and spatially directed surface modifications

- Functional Off-Stoichiometry Thiol-ene-epoxy Thermosets Featuring Temporally Controlled Curing Stages via an UV/UV Dual Cure Process

- Reaction injection molding and direct covalent bonding of OSTE+ polymer microfluidic devices

- Synthetic microfluidic paper: high surface area and high porosity polymer micropillar arrays

- Simultaneous replication of hydrophilic and superhydrophobic micropatterns through area-selective monomer self-assembly

- Off-Stoichiometry Improves Photostructuring of Thiol-Enes Through Diffusion-Induced Monomer Depletion

- Light Converting Polymer/Si Nanocrystal Composites with Stable 60-70% Quantum Efficiency and their Glass Laminates

- Single-step imprinting of femtoliter microwell arrays allows digital bioassays with attomolar limit of detection

- Batch fabrication of polymer microfluidic cartridges for QCM sensor packaging by direct bonding

Conference publications

- Fabrication of nanochannels by replica molding using off-stoichiometry thiol-ene (OSTE) polymer

- LOW TEMPERATURE “CLICK” WAFER BONDING OF OFF-STOICHIOMETRY THIOL-ENE (OSTE) POLYMERS TO SILICON

- ONE STEP INTEGRATION OF GOLD COATED SENSORS WITH OSTE POLYMER CARTRIDGES BY LOW TEMPERATURE DRY BONDING

- Biosticker : patterned microfluidic stickers for rapid integration with microarrays

- High-resolution micropatterning of off-stochiometric thiol-enes (OSTE) via a novel lithography mechanism

- SUPERIOR DRY BONDING OF OFF-STOICHIOMETRY THIOL-ENEEPOXY (OSTE(+)) POLYMERS FOR HETEROGENEOUS MATERIALLABS-ON-CHIP

- Dry Transfer Bonding of Porous Silicon Membranes to OSTE(+) Polymer Microfluidic Devices

- RAPID PERMANENT HYDROPHILIC AND HYDROPHOBIC PATTERNING OF POLYMER SURFACES VIA OFF-STOICHIOMETRY THIOL-ENE (OSTE) PHOTOGRAFTING

- Integration of a QCM with an OSTE cartridge

- Simple integration of a biosensor with an OSTE polymer cartridge by low temperature dry bonding

- ROBUST MICRODEVICE MANUFACTURING BY DIRECT LITHOGRAPHY AND ADHESIVE-FREE BONDING OF OFF-STOICHIOMETRY THIOL-ENE-EPOXY (OSTE+) POLYMER

- A polymer neural probe with tunable flexibility

- Integration Of Polymer Microfluidic Channels, Vias, And Connectors With Silicon Photonic Sensors By One-Step Combined Photopatterning And Molding Of OSTE

- Rapid Fabrication Of OSTE+ Microfluidic Devices With Lithographically Defined Hydrophobic/ Hydrophilic Patterns And Biocompatible Chip Sealing

- Low temperature adhesive wafer bonding using OSTE(+) for heterogeneous 3D MEMS integration

Dissertations

- Development of materials, surfaces and manufacturing methods for microfluidic applications

- Polymer microfluidic systems for samplepreparation for bacterial detection

- From Macro to Nano : Electrokinetic Transport and Surface Control

- Polymer Components for Photonic Integrated Circuits

- OSTE Microfluidic Technologies for Cell Encapsulation and Biomolecular Analysis

- Thiol-ene and Thiol-ene-epoxy Based Polymers for Biomedical Microdevices

- Digital Electrical DNA Sensing

- Thiol-ene Nanostructuring

- Synthetic Paper for Point-of-Care Diagnostics : Capillary control, surface modifications, and their applications

- Recreating the microenvironment of the neurovascular unit