Reliability Centered Asset Management (RCAM)

Reliability Centered Asset Management (RCAM) and Predictive Maintenance using condition monitoring data for Asset Management – with power system applications

Books and book chapters

- L. Bertling Tjernberg, (2023). Reliability-Centered Asset Management with Models for Maintenance Optimization and Predictive Maintenance: Including Case Studies for Wind Turbines In J. Tietjen, M. D. Ilic, L. Bertling Tjernberg, N. N. Schulz (Eds.), Women in Power Research and Development Advances in Electric Power Systems. (pp. 87-155) Springer Cham, DOI https://doi.org/10.1007/978-3-031-29724-3 July 2023.

- 2. Y. Cui, J. Eduardo Urrea Cabus, L. Bertling Tjernberg, (2023). A Fault Detection Approach Based on Autoencoders for Condition Monitoring of Wind Turbines, In K. . Wang, J. Tietjen, (Eds.), Women in Renewable Energy. (pp. 93-211), Springer Cham, DOI https://doi.org/10.1007/978-3-031-28543-1 June 2023.

- 1. L. Bertling Tjernberg, Infrastructure Asset Management with Power System Examples, CRC Press Taylor and Francis, First Edition, https://doi.org/10.1201/9781351057417, April 2018.

Most recent publication:

- G. Lal Rajora, M. A. Sanz-Bobi, L. Bertling Tjernberg, J. Eduardo Urrea Cabus, A review of asset management using artificial intelligence-based machine learning models: Applications for the electric power and energy system, IET Generation, Transmission, and Distribution, June 2024. https://doi.org/10.1049/gtd2.13183

Brief about the topic

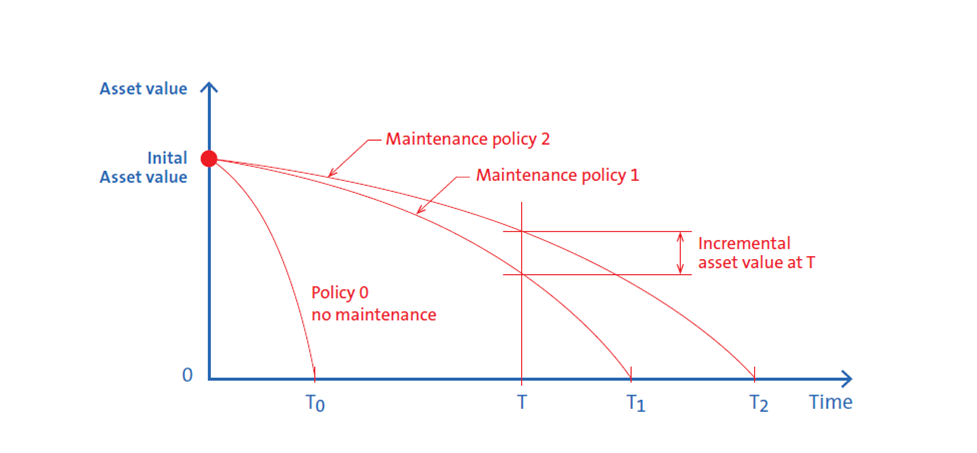

value of making smart decisions gives a reason for adopting Asset Management (AM). AM is a broadly used concept in the financial or engineering sector. “Asset Management is defined as a coordinated activity of an organization to realize value from assets”. The first step of AM is always the motivation. In this research, the applications in focus are all related to the infrastructure of the electric power system, a technical system that has been identified as one of the most important inventions of the past century. Access to electricity for lighting and transportation was fundamental for the industrial revolution. Today electricity is essential to the digital society. A future trend is the return to use electricity for transportation making it possible to use renewable fuels. The electric power system is an enabler for the transition into a sustainable energy system, also referred to as Smart Grid (SG). The figure below gives an illustration of the impact of maintenance policies on life curves (Figure 2.1 Bertling Tjernberg, CRC press 2018) and consequently on the value of preventive maintenance for AM.

The Reliability Centered Maintenance (RCM) method is a structured approach that focuses on reliability aspects when determining maintenance plans. The concept of RCM was established in 1978 by Nowlan and Heap. They were active in the commercial aviation industry. The need to improve reliability while containing the cost of maintenance was the driving factor behind this work. Maintenance and reliability are important because of the large costs associated with maintenance tasks and costs due to the loss of production and breakdowns. Breakdowns can also lead to consequences that affect the environment or personal safety. These aspects could also be taken into consideration when performing an RCM analysis.

This research presents the Reliability Centered Asset Maintenance (RCAM) method. The RCAM method combines the proven method of RCM with quantitative maintenance optimization techniques. The RCAM method was originally developed for the application of electric power distribution systems by Bertling in 2002 and was later shown as promising for the maintenance strategy selection and optimization of wind turbines.

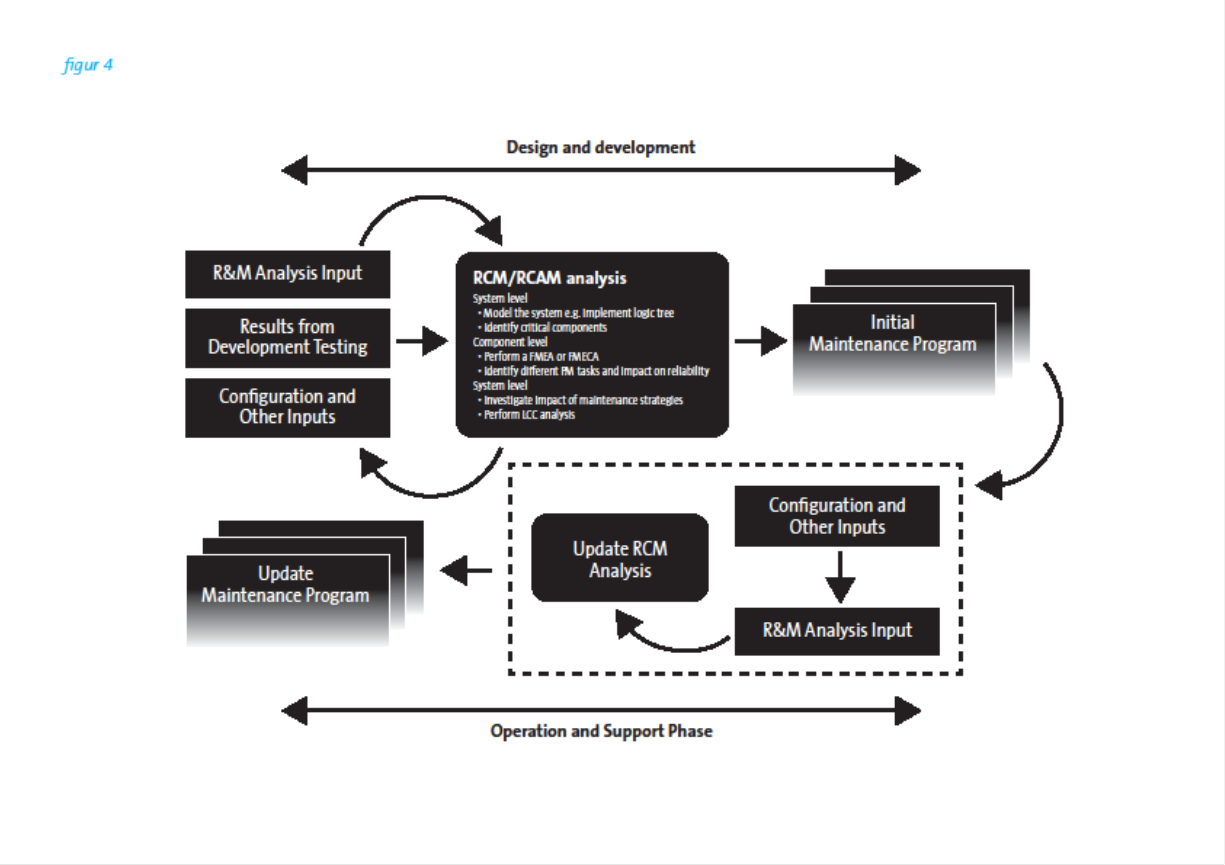

The figure below gives an overview of the steps of the RCM and RCAM process. It is outgoing from the: IEEE, IEEE Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems, The Gold Book. IEEE Std 493-2007, February 2007. (Figure 4.3 in Bertling Tjernberg, CRC press 2018). Note that the process includes the operation and support phase and not only the design and development.