Impressive projects in mechatronic’s “Grand Finale”

As most events these days, the “The Grand Finale”, the demo session of the Mechatronic Capstone Course was given digitally. Despite that, spirit was up when efforts and hard work from almost a year were presented an afternoon in December.

Around 60 students have been involved in the seven projects, which this year have had unusual challenges with a pandemic.

“The students have been working their butt off to the bitter end. It’s been tough during the pandemic since we’ve had restricted access to rooms, labs and equipment”, says Björn Möller, responsible for the course.

The projects are both research oriented and projects directly directed to commercial companies.

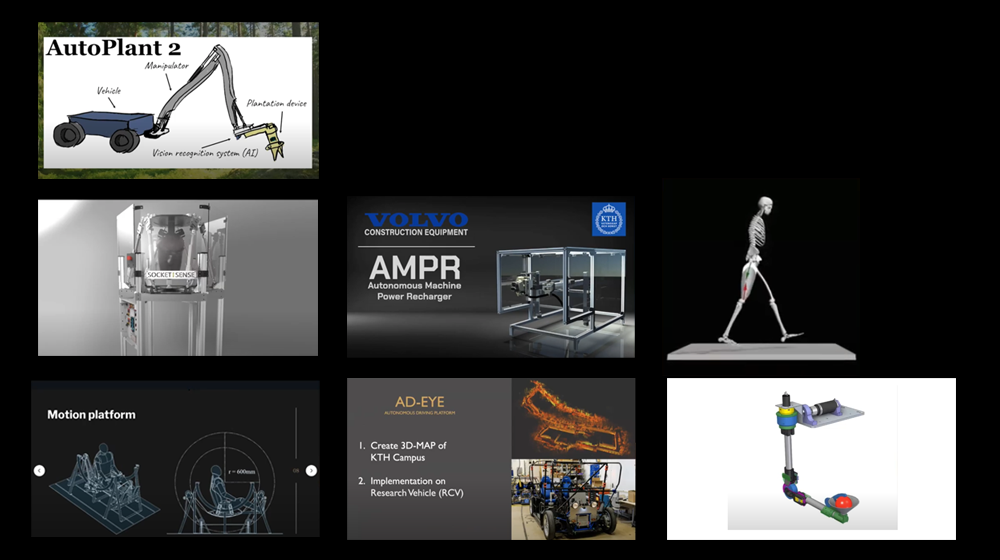

For example, one group has been working with Volvo Construction Equipment, developing charging stations for Volvo’s autonomous quarry carriers.

Another project got an assignment for a division of Meta Aerospace group, working with advanced flight simulations. They created a motion platform that enhance the VR experience in a simulated airplane.

The team working with AD-eye – the ongoing research project on an autonomous car - developed 3D maps of campus. Socket sense talked about tailor made prothesis with the help of sensors. Viewers also got presentations about a juggling robot, and two teams who wanted to improve the reforestation process with an autonomous planting machine.

Have the pandemic circumstances affected the quality of the work?

” The level of this year's projects has exceeded my expectations. I even want to say that the level has been higher than before. Running this course offline is an impossibility as it involves so much physical work. However, I like the fact that presentations and seminars have gone well to run digitally. What I, as the course coordinator, have raised as strongly negative is the lack of contact with the students. You do not get to know them via digital means”, Björn Möller says.

Text: Anna Gullers