AutoPlant

To implement a collaborative project with a focus on economically, ecologically and socially sustainable technology solutions for gentle and productive forest rejuvenation through automation.

AutoPlant is a Vinnova-funded collaboration project between the parties Skogforsk, LTU, KTH, Bracke, the Forestry Technology Cluster, SCA, Södra, Sveaskog and Holmen.

The project is part of the Challenge-Driven Innovation initiative, Stage 2, and runs from 15 February 2021 to 15 February 2023. The goal is to implement a collaborative project with a focus on economically, ecologically and socially sustainable technology solutions for gentle and productive forest rejuvenation through automation. In order to increase gender equality in the forestry industry in the long term, great emphasis will be placed on how the project is communicated.

The forest is an important resource in a bio-based society, where forest materials can help enable the phasing out of fossil products. For this to work, forest cultivation requires sustainable practices for the rapid establishment of seedlings and high growth.

An additional issue is finding labourers for the physically demanding manual planting that is involved today.

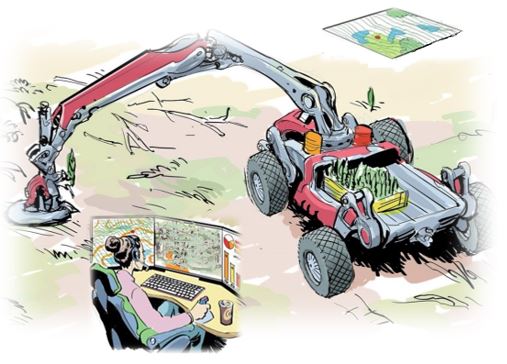

This project will therefore develop and test an autonomous forest rejuvenation machine with high precision, low environmental impact and a good working environment.

To achieve the goals, a number of sub-products will be developed during Stage 2, identified in the work packages (WP) below.

WP1 will develop a tool for system analysis where different choices in technology development are continuously tested to evaluate the impact on productivity, proportion of disturbed land, etc.

WP2 will involve the technical development of the soil preparation and planting unit.

In WP3, the sensor systems that the machine needs to navigate, select the planting point and meet the safety requirements will be developed.

During WP4 the tools for route planning, safety systems, decision-making and planting evaluation will be created.

In WP5, the different parts will be integrated with each other on a test platform, and field tests will be performed in WP6, both for the individual development steps and products and for the whole machine.

The KTH Mechatronics group is involved in a number of the work packages. For example, in WP2, the Masters level Mechatronics Advanced Courses (MF2058 and MF2059) includes a project where a group of students look at the precision control of the robotic arm and, with the help of image recognition, position the arm to achieve suitable planting points. The work also includes ensuring that the seedling is planted correctly.

Within WP4, PhD student Gustav Sten is working with the autonomous route planning of the planting machine. Gustav's main supervisor is Lei Feng and assistant supervisor Björn Möller. The work is a continuation of a previous project, Auto2, which was completed in 2020. Scanned data, soil conditions, planting information, etc is evaluated to create a global route for the planting machine. Since not everything can be predicted, local route planning is also necessary to carry out the work.

Within WP5 and WP6, Gustav's work will be implemented and tested. The goal is a "proof of concept" for autonomous afforestation (the establishment of a forest or stand of trees in an area where there was no previous tree cover) within the time frame of the AutoPlant project.

To tackle the challenges facing innovation, a strong consortium of manufacturers, researchers and users has been put together to consider the entire chain - from the seedlings in the nursery to the well-being of the young forest.

This project will be a great success if the autonomous forest rejuvenation machine we develop can increase plant survival. Increased growth creates better conditions for a bio-based society and more carbon dioxide is absorbed, which is positive for the climate. It would also increase Sweden's competitiveness and contribute to maintaining a high reputation for Swedish forest technology.

The test platforms currently available within AutoPlant are shown in the figures below. For more information on this project, please contact Björn Möller (bjornmm @kth.se).