PICTORIAL - Predictive Intelligent Control for Resistance Welding

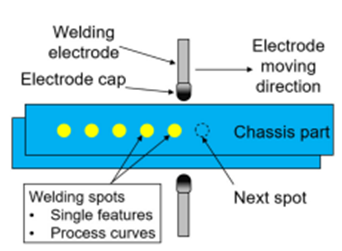

The primary contribution of this project is to develop machine learning (ML) models for the quality control of resistance spot welding (RSW) in the automotive industry, giving real-time cognitive support to personnel involved in production.

A distinct approach to training the ML models is to apply real production data from the automotive factories, which is rare in literature. Previously, simulated or experimental data have been used. Resistance welding is the predominate method in automotive industry today. The developed models will make it easier to reduce material extraction through increased use of circular, thinner and more advanced materials that are demanding to join.

New materials and new possibilities regarding sensors and computing systems will, together with the new predictive intelligent digital control system developed in this project, make a huge step in manufacturing capability.

Expected results and effects

The new predictive intelligent digital control system developed in the project, will make a leap forward in the quality assessment of RSW, the most used joining method within automotive. The project addresses the FFI sub-programme’s mission 2b), “Social sustainability throughout the value chain, e.g., Retain employees and attract new skills through techniques and solutions for cognitive and physical support ...”. At the same time, it will increase the digitalization knowledge in automated welding production.

Planned approach and implementation

Participants in the project consist of people with deep knowledge in production and spot welding, and in machine learning (ML). In the start-up of the project, time will be used to find a common language. Then relevant production data must be retrieved, after which the data must be curated and significant data translated into data language. Several different ML algorithms will be evaluated and combined, then trained against the acquired and curated data sets. When the final model is chosen, it will be tested in a demonstrator in industry.